168x Filetype PDF File size 1.44 MB Source: www.s-d-a.sk

EUROPE

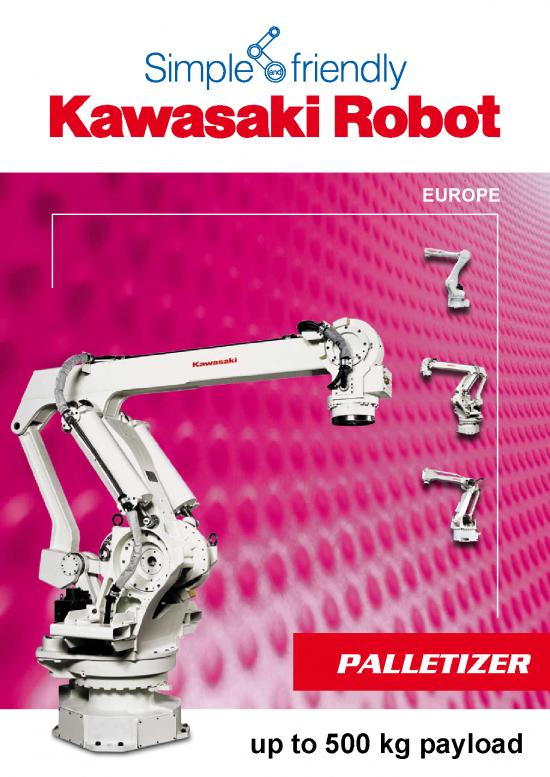

PALLETIZER

up to 500 kg payload

RD / ZD / MD

Series

»Simple and friendly« »40 years of experience and Kawasaki Palletizer

INTO THE FUTURE state-of-the-art robot techno-

logy« Synergy Power

An extremely compact and light-weight design Using the existing robot series, Kawasaki Robotics The data is telling its own tale! From 2,800 cycles

Palletizing jobs in different forms the basis for high speeds and rigidity as well developed the Palletizer Series. Within this series, per hour (see table) of the RD080N up to 500 kg

weight classes are the domain as an enormous reach. robots of the R-, Z-, and M- Series are used as payload of the MD500N, these robots are building

of this application orientated the basis for the equivalent palletizer. Especially a powerful and varied selection for your highest

robot series designed for palletizing, these robots are the ideal demands.

»Your goal is our task« working machines for this application.

It was Kawasaki‘s intelligence and flexibility which

made them build the most powerful robots in their

class. Combined with a high-end control system, Flexibility

they reliably meet the demands of the most varied The right robot for each type of palletizing

application fields – now, in the near and far future. application. Cycle time, payload or max. working

envelope. Based on the application focus you

can find the applicable Robot Model to do the

duty with maximum power.

2 3

RD / ZD / MD

Series

MO DEL RD080N ZD130S ZD250S MD400N MD500N Standard specifications

Degrees of Freedom 4 Axes

Maximum Reach*1 2100 mm 3255 mm 3255 mm 3142 mm 3142 mm

Maximum Payload 80 kg 130 kg 250 kg 400 kg 500 kg 1175 1967

2065 Working range

Axis 1 ±180° ±180° ±180° ±180° ±180° 325 1740 based on point P

Axis 2 +140° ~ -105° +90° ~ -50° +90° ~ -50° +90° ~ -45° +90° ~ -45°

Maximum Stroke

Axis 3 +40° ~ -205° +15° ~ -120° +15° ~ -120° +14° ~ -125° +14° ~ -125°

Axis 4 ±360° ±360° ±360° ±360° ±360° 250

Axis 1 180°/s 135°/s 95°/s 80°/s 70°/s Point P

Axis 2 180°/s 110°/s 90°/s 70°/s 65°/s

Maximum Speed

Axis 3 175°/s 130°/s 95°/s 70°/s 45°/s

Axis 4 360°/s 400°/s 190°/s 180°/s 160°/s

2 2 2 2 2 1100

Max. torque of inertia (payload) Wrist 13.7 kg/m 50 kg/m 100 kg/m 200 kg/m 250 kg/m

Repeatability ± 0.07 mm ± 0.5 mm ± 0.5 mm ± 0.5 mm ± 0.5 mm

(Measure Point: Center of Flange) 2510

3521

Weight 540 kg 1350 kg 1350 kg 2650 kg 2680 kg

2

Palletizing performance data * 2800 cycles/h 1800 cycles/h 850 cycles/h 740 cycles/h 600 cycles/h

(vertical/horizontal) (80 kg) (60 kg) (250 kg) (400 kg) (500 kg) 1160

2

RD080N* : 75 mm/900 mm 3

3 * 900 cycles/h 1500 cycles/h

RD080N* : 400 mm/2000 mm (80 kg) (130 kg)

ZD/MD: 400 mm/2000 mm

600

Controller E42 E43 E43 E44 E44 MD500N: 856

588 598 600 MD400N: 624

Color Munsell 10GY9/1 equivalent

Installation Floor MD400N/MD500N

Temperature 0-45°

Humidity 35~85% (no Dew, nor Frost allowed)

Ambient Conditions Installation Ambience must be free of:

Others • Inflammable or corrosive Liquid or Gas

• Electric Noise Interferences

input 12 12 12 12 12

Application Media Upper Arm output 8 8 8 8 8 Working range

based on point P

air pipes 2 x 10 mm Ø 2 x 12 mm Ø 2 x 12 mm Ø 2 x 12 mm Ø 2 x 12 mm Ø 370.8 2100

150 1080

1

* Distance between center of Axis 1 and center of flange.

RD080N, MD400N and MD500N are using a compensating 5th axis to eliminate the parallelogram 244 298

158

165

870 1050 Point P

1400 2079.2

1696.5

680

277 307

1231.5

RD080N

4 5

RD / ZD / MD

Series

Standard specifications MODEL E42 E43 E44

Number of Controlled Axes 5 (16) 4 (16) 5 (16)

Servo Motors Brushless AC Servomotors

Position Detectors Absolute Encoder

998 2257

300 1450 255 Working range Servo System Full digital servo system

based on point P

Programming Block or AS-Language

Coordinate Systems Joint, Base, Tool, external Tool

270

Motion Control Joint-, Linear- and Circular interpolated

Point P External Motor power, Signal HOLD, etc.

Input 32 (optional 128)

1250

Signals Output 32 (optional 128)

Analogue Input 8/16

3075.3 (optional)

Analogue Output 4/8/12/16

(optional)

670

Memory 8 MB (ca. 80.000 steps)

External Memory 2 x USB

PC, Network, etc. 2 x RS-232C, 2 x Ethernet

810 Data Interfaces © © © © © ©

Fieldbus (optional) DeviceNet , PROFIBUS , PROFINET , INTERBUS-S , Ethernet/IP , CC-Link ,

© © ©

CANopen , Modbus TCP , Control Net

Teach Pendant 6.4“ TFT LCD with Touch Panel, Emergency Stop SW, Teach-Lock, Deadman SW,

ZD130S/ZD250S Motor power, Program start, Hold/Run

Operation Panel Emergency Stop SW, Control Power, TEACH/REPEAT

Cable Length (Controller – Arm), 10 m (Arm: optional up to 40 m), (TP: optional up to 30 m)

(Controller – Teach Pendant)

Dimensions (WxDxH mm) 730x550x1200

Weight (kg) 195

Power Requirements AC 380-415V ± 10%, 50/60Hz, 3 Phases, 9,9kVA

The E-Controller – technically mature, easy to operate Ground <100Ω, Max. Leakage Current 10mA

and powerful Safety Category 3, Performance Level d (EN ISO13849-1:2008)

Ambience Temperature / Humidity 0-45°C / 35-85% (no Dew, nor Frost allowed)

Compact, upgradeable and user-friendly System Color Munsell 10GY9/1 equivalent

A maximum of 10 external axes may be integrated, Ultra-fast execution of programs, loading and storing Note: Not all Options can be combined.

up to three of which in the controller housing (E4x). processes as well as a precise continuous-path con-

All established bus systems (Interbus, Profibus, Pro- trol and much more thanks to the up-to-date proces-

fiNet…) are supported. The integrated Soft PLC may sor design and powerful components. 8 MB RAM

be edited via Teach Pendant or even more comfortab- (80,000 steps) and USB interface as standard.

ly at the PC (option). Custom-tailored user interfaces

may be programmed and used for the simplified Maintenance

control of the robot and also peripheral devices. »Simple and friendly« – Due to the optimized modular

Motor voltage ON and program start may be activa- configuration of the Kawasaki control, maintenance

ted directly via the manual control unit. The parallel work is exceptionally user-friendly. Furthermore

display of two information screens (e.g. position and integrated service and diagnosis tools guarantee

signal data) facilitates the process control. increased safety in operation. Remote diagnosis via

Ethernet is also included in the standard package.

6 7

no reviews yet

Please Login to review.