258x Filetype PDF File size 0.29 MB Source: www.nesc.wvu.edu

A NATIONAL DRINKING WATER CLEARINGHOUSE FACT SHEET

Membrane Filtration

Summary

A membrane or, more properly, a semipermeable membrane, is a thin layer of material

capable of separating substances when a driving force is applied across the membrane.

Once considered a viable technology only for desalination, membrane processes are increas-

ingly employed for removal of bacteria and other microorganisms, particulate material, and

natural organic material, which can impart color, tastes, and odors to the water and react

with disinfectants to form disinfection byproducts (DBP). As advancements are made in

membrane production and module design, capital and operating costs continue to decline.

The pressure-driven membrane processes discussed in this fact sheet are microfiltration (MF),

ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO).

Membrane Filtration: Alternative rules have increased interest in NF and

to Conventional Filtration UF membranes for DBP precursor removal.

Membrane filtration systems’ capital costs, on Potable water treatment has traditionally

a basis of dollars per volume of installed treat- focused on processes for liquid-solid separation

ment capacity, do not escalate rapidly as plant rather than on processes for removing dissolved

size decreases. This factor makes membranes contaminants from water. Thus, the effect of

quite attractive for small systems. In addition, the 1996 Safe Drinking Water Act (SDWA)

for groundwater sources that do not need amendments has been to encourage water

pretreatment, membrane technologies are treatment professionals to consider the more

relatively simple to install, and the systems unconventional treatment processes, such as

require little more than a feed pump, a cleaning membrane technologies, alone, or in conjunc-

pump, the membrane modules, and some tion with liquid-solid separation, to meet

holding tanks. According to a 1997 report by current regulations.

the National Research Council, most experts

foresee that membrane filtration will be used Comparing Membrane Filtration

with greater frequency in small systems as the Systems

complexity of conventional treatment processes

for small systems increases. While all types of membranes work well under

proper conditions, choosing the most appro-

New Regulations Favor Membrane priate membrane for a given application still

Technologies remains crucial. (See Figure 1.) In many cases,

Membrane processes have become more attrac- selection is complicated by the availability of

tive for potable water production in recent years new types of membranes, applications, or by

due to the increased stringency of drinking site-specific conditions. Bench and pilot tests

water regulations. Membrane processes have are powerful tools for situations where process

excellent separation capabilities and show risks and uncertainties exist or the cost impacts

promise for meeting many of the existing and from problems are potentially high. PAGE

anticipated drinking water standards. The

Membrane classification standards vary consid-

one

Surface Water Treatment Rule (SWTR) and erably from one filter supplier to another. What OF

the anticipated Groundwater Disinfection Rule EIGHT

have led to the investigation of UF and MF

for turbidity and microbial removal. The new

Disinfectants/Disinfection Byproduct (D/DBP)

NATIONAL DRINKING WATER CLEARINGHOUSE

Membrane Filtration

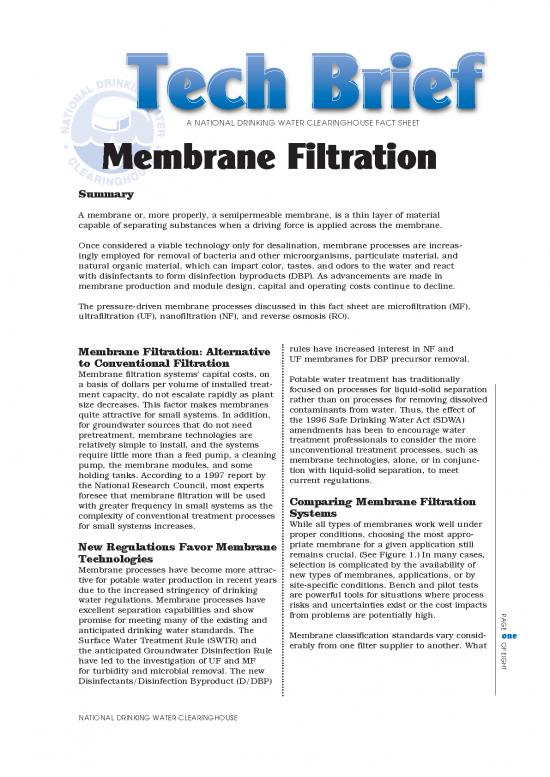

Figure 1: Generalized Membrane Process Selection Chart

Is treatment goal to remove particles >0.2 micron? LEGEND

Yes MF = Microfiltration

No UF = Ultrafiltration

MF NF = Nanofiltration

Can dissolved contaminants be precipitated, RO = Reverse Osmosis

coagulated, or absorbed? ED/EDR = Electrodialysis Reversal

Yes MW = Molecular Weight (in daltons)

No TDS = Total Dissolved Solids

MF or UF

Is dissolved organics removal needed? Yes Is inorganic ion removal needed?

No Yes

Are the inorganic ions to be removed multivalent Are the ions multivalent No

(e.g., a softening application)? (e.g., a softening application)?

Yes Yes No

NF No

NF RO

Is the required TDS removal greater Are the dissolved organics

than 3,000 mg/L? greater than 10,000 MW?

Yes Yes

RO No No

UF

Is silica scale a concern? Are the dissolved organics

greater than 400 MW?

Yes No

Yes No

ED/EDR RO or ED/EDR RO

NF

NOTE: This simplified chart is based on common assumptions and should not be

applied to every situation without more detailed analysis.

ASSUMPTIONS

A. Relative Cost B. Removals

• MF < UF < NF < RO or ED/EDR • MF–particles > 0.2 Micron

• If TDS removal > 3,000 mg/L, • UF–organics > 10,000 MW, virus,

RO or ED/EDR may be less costly and colloids

• NF–organics > 400 MW and hardness ions

• RO–salts and low MW organics

• ED/EDR–Salts

• Particles include Giardia, Cryptosporidium,

bacteria, and turbidity

Reprinted from Proceedings of the 1993 Membrane Technology Conference, by permission.

Copyright ©1993, American Water Works Association.

one supplier sells as a UF product, another Microfiltration (MF)

manufacturer calls a NF system. It is better to MF is loosely defined as a membrane separation

EIGHTlook directly at pore size, molecular weight process using membranes with a pore size of

cutoff (MWCO), and applied pressure need- approximately 0.03 to 10 microns, a MWCO of

OF

ed when comparing two membrane systems. greater than 100,000 daltons, and a relatively

two

MWCO, which can be regarded as a measure low feedwater operating pressure of approxi-

of membrane pore dimensions, is a specifica- mately 100 to 400 kPa (15 to 60 psi). Represen-

PAGE tative materials removed by MF include sand,

tion used by membrane suppliers to describe a

membrane’s retention capabilities. silt, clays, Giardia lamblia and Cryptosporidium

TEN • MARCH 1999

cysts, algae, and some bacterial species. (See powdered activated carbon (PAC), has been

Figure 2 and Table 1.) MF is not an absolute employed. In some cases, the cake layer built

barrier to viruses; however, when used in up on the membrane during the water produc-

combination with disinfection, MF appears tion cycle can remove some organic materials.

to control these microorganisms in water.

It may be necessary to adjust the feedwater pH

The primary impetus for the more widespread by chemical dosing prior to membrane filtration

use of MF has been the increasingly strin- in order to maintain the pH within the rec-

gent requirements for removing particles and ommended operating range for the membrane

micro-organisms from drinking water supplies. material employed. It should be noted that pH

Addi-tionally, there is a growing emphasis on adjustment is not required for scaling control,

limiting the concentrations and number of since MF membranes do not remove uncom-

chemicals that are applied during water treat- plexed dissolved ions.

ment. By physically removing the pathogens,

membrane filtration can significantly reduce MF membranes, under the most conservative

chemical addition, such as chlorination. conditions, appear to act as an absolute bar-

rier to selected bacteria and protozoan cysts

Another application for the technology is for and oocysts. Unlike UF however, MF does not

removal of natural or synthetic organic mat- remove appreciable densities of viruses. There-

ter to reduce fouling potential. In its normal fore, it is necessary to complement MF with a

opera- tion, MF removes little or no organic post-membrane disinfection process. Chemical

matter; however, when pretreatment is applied, disinfection may be employed by applying

in-creased removal of organic material, as well chlorine, chlorine dioxide, or chloramines;

as a retardation of membrane fouling can however, long contact times are required to

be realized. inactivate viruses.

Two other applications involve using MF as EQUIPMENT

a pretreatment to RO or NF to reduce fouling For municipal-scale drinking water applica-

potential. Both RO and NF have been tradi- tions, the commercially available membrane

tionally employed to desalt or remove hardness geometries that are the most commonly

from groundwater. em-ployed are spiral wound, tubular, and hol-

low capillary fiber. However, spiral-wound con-

PROCESS figurations are not normally employed for MF

MF membranes provide absolute removal of due to the flat-sheet nature of the membrane,

particulate contaminants from a feed stream by which presents difficulties in keeping the mem-

separation based on retention of contaminants brane surface clean. Unlike spiral-wound mem-

on a membrane surface. It is the “loosest” of the branes, hollow-fiber and tubular configurations

membrane processes, and as a consequence allow the membrane to be backwashed, a pro-

of its large pore size, it is used primarily for cess by which fouling due to particulate and

removing particles and microbes and can be organic materials is controlled.

operated under ultralow pressure conditions.

Membrane “package” plants are normally

In the simplest designs, the MF process involves employed for plants treating less than one

prescreening raw water and pumping it under million gallons per day (mgd). The components

pressure onto a membrane. In comparison of the plant may include prescreens, a feed

to conventional water clarification processes, pump, a cleaning tank, an automatic gas

where coagulants and other chemicals are backwash system, an air compressor, a mem-

added to the water before filtration, there are brane integrity monitor, a backwash water

few pretreatment requirements for hollow-fiber transfer tank, a pressure break reservoir, an

systems when particles and microorganisms air filter for the gas backwash, controls for the

are the target contaminants. programmable logic controller, and a coalescer.

PAGE

Prefilters are necessary to remove large particles OPERATION AND MAINTENANCE

that may plug the inlet to the fibers within the In MF, there are two methods for maintaining

three

membrane module. More complex pretreatment or re-establishing permeate flux after the mem- OF

strategies are sometimes employed either to branes are fouled: EIGHT

reduce fouling or enhance the removal of virus- • Membrane backwashing: In order to prevent

es and dissolved organic matter. In such the continuous accumulation of solids on the

cases, pretreatment by adding coagulants or membrane surface, the membrane is

NATIONAL DRINKING WATER CLEARINGHOUSE

Membrane Filtration

backwashed. Unlike backwashing for con- important subject, which should be thoroughly

ventional media filtration, the backwashing researched in order to have a better understand-

cycle takes only a few minutes. Both liquid ing of this phenomenon and its mechanisms.

and gas backwashing are employed with MF

technology. For most systems, backwashing PROCESS

is fully automatic. If backwashing is inca- UF is a pressure-driven process by which

pable of restoring the flux, then membranes colloids, particulates, and high molecular mass

are chemically cleaned. The variables that soluble species are retained by a process of size

exclusion, and, as such, provides means for

should be considered in cleaning MF mem concentrating, separating into parts, or filter-

branes include: frequency and duration of ing dissolved or suspended species. UF allows

cleaning, chemicals and their concentra- most ionic inorganic species to pass through

tions, cleaning and rinse volumes, tempera- the membrane and retains discrete particulate

ture of cleaning, recovery and reuse of matter and nonionic and ionic organic species.

cleaning chemicals, neutralization and

disposal of cleaning chemicals. UF is a single process that removes many

• Membrane pretreatment: Feedwater pretreat water-soluble organic materials, as well as

ment can be employed to improve the level microbiological contaminants. Since all UF

of removal of various natural water constitu- membranes are capable of effectively straining

ents. It is also used to increase or maintain protozoa, bacteria, and most viruses from water,

transmembrane flux rates and/or to retard the process offers a disinfected filtered product

fouling. The two most common types of with little load on any post-treatment steril-

pretreatment are coagulant and PAC addition. ization method, such as UV radiation, ozone

treatment, or even chlorination.

Ultrafiltration (UF) Unlike RO, the pretreatment requirement for UF

UF involves the pressure-driven separation of is normally quite low. Fortunately, due to the

materials from water using a membrane pore chemical and hydrolytic stability of UF mem-

size of approximately 0.002 to 0.1 microns, an brane materials, some of the pretreatments

MWCO of approximately 10,000 to 100,000 essential for RO membranes, such as adjust-

daltons, and an operating pressure of approxi- ment of pH or chlorine concentration levels,

mately 200 to 700 kPa (30 to 100 psi). UF will do not apply. However, it may be necessary to

remove all microbiological species removed by adjust the pH to decrease the solubility of a

MF (partial removal of bacteria), as well as some solute in the feed so that it may be filtered out.

viruses (but not an absolute barrier to viruses)

and humic materials. (See Figure 2 and Table UF is designed to remove suspended and

1.) Disinfection can provide a second barrier to dissolved macromolecular solids from fluids.

contamination and is therefore recommended. The commercially available modules are there-

The primary advantages of low-pressure UF fore designed to accept feedwaters that carry

membrane processes compared with conven- high loads of solids. Because of the many uses

tional clarification and disinfection (postchlori- for UF membranes, pilot studies are normally

nation) processes are: conducted to test how suitable a given stream is

• No need for chemicals (coagulants, floccu- for direct UF.

lants, disinfectants, pH adjustment); Water containing dissolved or chelated iron and

• Size-exclusion filtration as opposed to media manganese ions needs to be treated by an

depth filtration; adequate oxidation process in order to precipi-

• Good and constant quality of the treated tate these ions prior to UF membrane filtration,

water in terms of particle and microbial as with all membrane processes. This is recom-

removal; mended to avoid precipitation of iron and

• Process and plant compactness; and manganese in the membrane, or even worse,

EIGHT• Simple automation.

on the permeate side of the membrane (mem-

OF brane fouling during the backwash procedure).

Fouling is the limiting phenomenon responsible

four Preoxidation processes generally used include

for most difficulties encountered in membrane aeration, pH adjustment to a value greater than

technology for water treatment. UF is certainly

PAGE eight, or addition of strong oxidants, such as

not exempt from this fouling control problem. chlorine, chlorine dioxide, ozone, or potassium

Therefore, membrane productivity is still an

TEN • MARCH 1999

no reviews yet

Please Login to review.