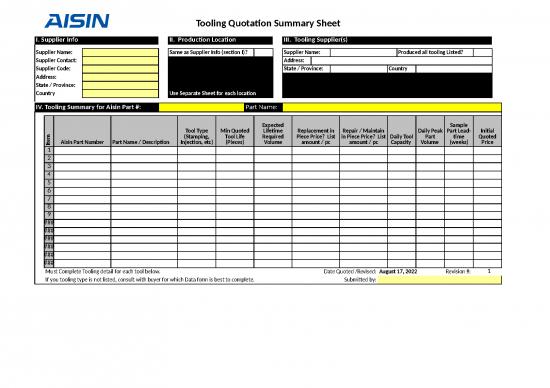

| Tooling Quotation Summary Sheet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| I. Supplier Info |

|

II. Production Location |

|

|

|

|

|

|

|

|

|

|

|

III. Tooling Supplier(s) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Supplier Name: |

|

|

Same as Supplier Info (section I)? |

|

|

Supplier Name: |

|

Produced all tooling Listed? |

|

|

|

|

|

Yes |

|

|

|

|

|

|

|

|

|

|

|

|

| Supplier Contact: |

|

|

|

|

|

|

Supplier Name: |

|

|

Address: |

|

|

|

|

|

No |

|

|

|

|

|

|

|

|

|

|

|

--44790-Rev1 |

| Supplier Code: |

|

|

|

|

|

|

Address: |

|

|

State / Province: |

|

Country |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Address: |

|

|

|

|

|

|

State / Province: |

|

|

Supplier Name: |

|

List tool for each supplier in comment |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| State / Province: |

|

|

|

|

|

|

Country |

|

|

Address: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Country |

|

|

|

|

|

|

Use Separate Sheet for each location |

|

State / Province: |

|

Country |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| IV. Tooling Summary for Aisin Part #: |

|

Part Name: |

|

|

|

|

|

|

Tool Type Choices |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

Aisin Part Number |

Part Name / Description |

Tool Type (Stamping, Injection, etc) |

Min Quoted Tool Life (Pieces) |

Expected Lifetime Required Volume |

Replacement in Piece Price? List amount / pc |

Repair / Maintain in Piece Price? List amount / pc |

Daily Tool Capacity |

Daily Peak Part Volume |

Sample Part Lead-time (weeks) |

Initial Quoted Price |

|

|

Transfer Dies |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tandem Dies |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Progressive Die |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Blank Die |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Injection Mold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Insert Injection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Outsert Injection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Reaction Injection Mold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Compression Mold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Blow Mold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Vertical Mold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Unscrewing Mold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

2-Shot / Multiple Shot Mold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Shuttle Mold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Stack Mold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Other Stamping |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Other Injection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Must Complete Tooling detail for each tool below. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Date Quoted /Revised: |

August 17, 2022 |

Revision #: |

|

|

|

1 |

|

|

|

Al Casting Die |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If you tooling type is not listed, consult with buyer for which Data form is best to complete. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Submitted by: |

|

|

|

Gravity Casting Die |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Qty |

Add Detail Sheet |

|

|

|

|

|

|

|

|

|

|

Directions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Extrusion Die |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Stamping Dies |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

1) List each tool used to produce the quoted part number (s). If tooling is common to another Part, List "Common to Part" number in description cell and and only show tooling price on one part number.

2) Complete ALL Cells above for each Tool.

If multipe types of tools are listed (ex: Stamping), click on "Add Detail Sheet" for additional Sheets.

Detail sheets must be completed to finalize tool cost agreement. Initial quoted price above can only be validated and agreed based on compled detail sheets. |

|

|

|

Fixture |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Injection Molds |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

Gauge |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Casting Dies |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

Jig |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Compression Molds |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Extrusion Dies |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

Temporary - Use Injection Sheet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Blow Molds |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

Temporary - Use Injection Sheet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Jigs and Fixtures |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Guages |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For Aisin Internal Use Only |

|

|

|

|

|

|

|

|

|

|

|

1 |

|

1 |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| IV. Stamping Tooling Detail |

|

|

|

|

|

|

|

|

|

|

|

Supplier: |

|

|

|

|

Item #: |

|

|

|

|

Aisin Part #: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Material |

Part Material class |

|

|

|

|

|

|

|

|

|

Currency |

Tool Purchase currency |

|

|

|

|

|

|

|

|

|

Process |

Parts per Stroke |

|

|

|

|

|

|

|

|

Analysis |

Analysis required? |

|

|

|

|

|

|

|

|

|

|

|

|

|

Number of Processes |

|

Measure |

Tap |

Nut Insertion |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Specific Material / Grade |

|

|

|

|

|

|

|

|

|

Exchange Rate Used / USD |

|

|

|

|

|

|

|

|

|

Required Tonnage |

|

|

|

|

|

|

|

|

Iterations performed |

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dual Phase Material? |

|

|

|

|

|

|

|

|

|

Date paid: |

|

|

|

|

|

|

|

|

|

Actual (rated) tonnage |

|

|

|

|

|

|

|

|

Stamping process |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Size of (in mm) |

Length (mm) |

Width (mm) |

Thickness (mm) |

# of Die Shoes Mounted on this plate? |

|

# of Cams |

Width (mm) |

Quantity |

Operation # ( below) |

Custom? |

2nd Width (mm) |

2nd Quantity |

Operation # ( below) |

Custom? |

|

|

|

Tool Type |

|

Blank Area |

Blank area row |

|

|

Row |

549.99999999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Blank Size |

|

|

|

0 |

|

Single Action |

|

|

|

|

|

|

|

|

|

|

|

Form |

|

0 |

Progressive Dies |

|

1 |

0 |

|

2 |

550 |

1199.999999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Master Locator Plates |

|

|

|

0 |

|

Double Action |

|

|

|

|

|

|

|

|

|

|

|

Pierce |

|

|

Required Tonnage |

|

|

|

|

3 |

1200 |

4500 |

|

|

|

|

Cam Cost Adder - All Dies ($ per cam) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Die Shoe |

|

|

|

0 |

|

Aerial |

|

|

|

|

|

|

|

|

|

|

|

Trim |

|

|

0 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sub-Plates (lower) |

|

|

|

|

|

Polishing for A-surface appearance parts (area in cm2) - note on ISO View |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Coin |

|

Row # |

|

Base Tool Cost |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sub-Plates (Upper) |

|

|

|

|

|

Fingers |

|

|

|

Extra Design/Machining countoured Surface?(cm2) |

|

|

|

|

|

|

|

Flange |

|

1 |

1 |

1 |

|

Base Dies |

Deep Draw |

Measure, Tap & Nut Insertion |

CAM(s) |

Adjustment % |

Deep Draw Adj |

QDC Plates |

Bars & Fingers |

Other |

Total |

Cam Width |

|

0 |

76.2 |

Quantity |

Quantity |

Total |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

QTY |

Area (mm2) |

|

|

|

Servo Press? |

|

|

|

|

|

|

|

|

|

Bars |

|

|

|

Deep Draw /Crash Form? |

Deep Draw: the depth of the draw is > the distance across the narrowest portion of the opening created in the part or the draw depth in a single station is 2 X or more the min part width.

|

|

Operation #? |

|

|

|

|

|

|

Form |

|

2 |

0 |

0 |

Progressive |

$- |

|

0 |

$- |

#N/A |

|

$- |

$- |

$- |

#N/A |

Single Action Cam |

|

|

$1,250 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

QDC Plates |

|

|

|

|

|

|

|

|

|

X-hatched Die Shoes>12 ft? |

|

|

|

|

|

|

|

|

|

Closed Die (Set) Dimension (L x W x H) |

|

|

|

|

|

|

|

|

|

|

|

|

|

KO Pin? |

|

|

|

|

|

|

Bend |

|

3 |

0 |

0 |

Transfer |

$- |

0 |

0 |

$- |

#N/A |

0 |

$- |

$- |

$- |

#N/A |

Double Action Cam |

|

|

$1,750 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nitrogen Cyl Sets (dia) |

|

|

|

|

|

|

|

|

|

Developed Blank? |

|

|

|

|

|

|

|

|

|

Stroke Height Required: |

|

|

|

|

|

|

|

|

|

|

|

|

Feed Height Required |

|

|

|

|

|

|

Re-strike |

|

4 |

0 |

0 |

Tandem |

$- |

0 |

0 |

$- |

#N/A |

0 |

$- |

$- |

$- |

#N/A |

Aerial/Flying Cam |

|

|

$1,750 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nitrogen Tank |

|

|

|

|

|

|

|

|

|

Adjustable Form Mtl in Die? |

|

|

|

|

|

|

|

|

|

Comment or any additional info for tooling cost: |

|

|

|

|

Draw |

|

5 |

0 |

0 |

Blank |

$- |

|

0 |

$- |

#N/A |

|

$- |

$- |

$- |

#N/A |

Cam Width |

|

76 |

152.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guided Stripper Plates? |

|

|

|

|

|

|

|

|

|

Cast Die Shoes? |

|

|

|

|

|

|

|

|

|

|

|

|

Idle |

|

6 |

0 |

0 |

Other |

|

|

0 |

|

|

|

|

|

|

|

Single Action Cam |

|

|

$2,500 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Springs (dia) |

|

|

|

|

|

|

|

|

|

|

|

Weight (kg) |

|

|

|

|

Upper |

|

|

|

|

|

In-Die Measure |

|

7 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

Double Action Cam |

|

|

$3,500 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heel/Thurst Block Sets |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lower |

|

|

|

|

|

Tapping |

|

8 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

Aerial/Flying Cam |

|

|

$3,500 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Short Flange (list size) |

|

|

|

|

|

|

|

|

|

Total Tool Weight (kg) |

|

|

|

|

|

|

|

|

|

|

|

|

Nut Insertion |

|

9 |

0 |

0 |

|

Tandem Dies |

Transfer Dies |

|

|

|

Cam Width |

|

152 |

330 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type of Blank Process? |

|

|

|

|

|

|

|

|

# of Tool Sets Quoted |

|

|

|

|

|

|

|

This should only be greater than one if additional tool sets are needed to meet capacity (cycle time, not machine capacity)

1 |

|

|

|

|

Other |

|

10 |

0 |

0 |

|

(1) tandem Dies Only |

(1) Transfer Dies Only |

|

|

|

Single Action Cam |

|

|

$3,000 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mtl Lift Height (mm) |

Description (For ECI, describe Modification) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Yes |

Y |

11 |

0 |

0 |

|

Blank Pierce Trim Coin |

Flange Form Bend Restrike |

|

Draw |

Blank Pierce Trim Coin |

Flange Form Bend Restrike |

Draw |

(3) Transfer idle stations only |

|

|

Double Action Cam |

|

|

$4,750 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Operation: |

(blank, draw, pierce, trim, form, idle, restrike, Draw, In-Die Measurement, Nut Insertion, bend, Flange, coin, tapping, etc.)

List all idles

Type |

|

Strip / Blank Layout (For ECI's, note change areas) |

|

|

|

No |

N |

12 |

0 |

0 |

|

|

|

|

Aerial/Flying Cam |

|

|

$4,750 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

Rate Calc |

|

13 |

0 |

0 |

|

|

|

|

Cam Width |

|

330 |

508 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

0 |

|

14 |

0 |

0 |

# of Dies |

0 |

0 |

|

0 |

0 |

0 |

0 |

0 |

|

|

Single Action Cam |

|

|

$3,500 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

0 |

|

15 |

0 |

0 |

|

$6,000 |

$7,000 |

|

$8,000 |

$8,500 |

$9,500 |

$11,500 |

$2,500 |

|

|

Double Action Cam |

|

|

$6,000 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

0 |

|

16 |

0 |

0 |

Total |

$- |

$- |

|

$- |

$- |

$- |

$- |

$- |

|

|

Aerial/Flying Cam |

|

|

$6,000 |

0 |

|

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

0 |

|

17 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

Cam Width |

|

508 |

1016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

0 |

|

18 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

Single Action Cam |

|

0 |

$3,500 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

0 |

|

19 |

0 |

0 |

|

Part Material |

|

Shear |

|

|

|

|

|

|

|

Double Action Cam |

|

0 |

$6,000 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

0 |

|

20 |

0 |

0 |

|

270 |

|

Compound |

|

|

|

|

|

|

|

Aerial/Flying Cam |

|

0 |

$6,000 |

0 |

0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

0 |

|

21 |

0 |

0 |

|

>270 - 590 |

|

Progressive |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

22 |

|

0 |

|

>590 - 780 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Cam Total |

|

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

|

|

|

|

|

|

|

|

23 |

|

0 |

|

>780 - 980 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

Tool Estimate |

|

24 |

|

0 |

|

>980 - 11280 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|

|

|

|

|

|

|

Enter detail for each Station |

|

25 |

|

0 |

|

Galvanized |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

Replacement or Additional |

|

26 |

|

0 |

|

Aluminum |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

#VALUE! |

|

27 |

|

0 |

|

Stainless Steel |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

Part ISO View (For ECI's, note change areas) |

|

|

|

Total Tool Estimate including multiple tools |

|

|

|

|

|

Copper |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

17 |

|

|

|

|

|

|

|

|

#VALUE! |

IF material is Dual Phase, Cost Adder for 2nd phase material is not included. |

|

|

|

|

Other |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

19 |

|

|

|

|

|

|

|

|

|

|

Tool Lead-Time Estimate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

#VALUE! |

Weeks |

|

|

6.731 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

|

|

|

|

|

|

|

Lead Time Est. |

|

|

0 |

Tool Design & Try-out |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

|

|

|

|

|

|

|

#VALUE! |

Weeks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

26 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

27 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

28 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

29 |

|

|

|

|

|

|

|

|

|

In-house |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30 |

|

|

|

|

|

|

|

|

|

Local Vender |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Complete this section for ECI Modifications |

|

|

|

|

|

|

|

Overseas Parent |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cost Detail: |

$/Hr. |

Hours: |

Total: |

|

ECI Quoted Changes: Submit duplicate copy of this sheet with change details below for each ECI. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overseas Supplier |

|

|

|

Ejector Pins |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Design Labor - Mechanical |

|

|

$0 |

|

Previous ECI # |

Quoted Amt |

Change Description |

|

|

|

|

|

|

|

|

|

Add |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Design Labor - Electrical |

|

|

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Remove |

$0 |

|

|

Size Range |

Boss |

Base ~ 30 mm |

Clip Tower (H-Rib) |

Base ~ 30 mm |

Rib Change |

Part Surface/Thickness Change |

Parting Line Change |

Mechanical Slide/Lifter |

Hydraulic Slide |

Insert |

|

Design Labor - Pneumatic/Hydraulic |

|

|

$0 |

|

|

|

|

|

|

|

|

Boss |

|

|

|

|

|

|

|

Row # |

Lower |

Upper |

Add Boss |

Remove Boss |

Add Boss (With Sleeve) |

Remove Boss (With Sleeve) |

Add |

Remove |

New/ Heighten |

Remove/Shorten |

Modify Cavity (Machine) |

Modify Cavity (Weld+Machine) |

Modify Core (Machine) |

Modify Core (Weld+Machine) |

Addition of Radius (Non PL Mod) |

Modify Cavity (Machine) |

Modify Cavity (Weld+Machine) |

Modify Core (Machine) |

Modify Core (Weld+Machine) |

New Slide |

New Lifter |

Eliminate Slide |

Eliminate Lifter |

Modify Slide/Lifter (Machine) |

Modify Slide/Lifter (Weld+Machine) |

New Slide |

Eliminate Slide |

Modify Slide (Machine) |

Modify Slide (Weld+Machine) |

New Insert |

Modify |

|

Programming Labor - (CNC,EDM & CMM) |

|

|

$0 |

|

|

|

|

|

|

|

|

|

Add Boss |

|

$0 |

|

New |

|

|

1 |

0 |

30 |

0 |

|

|

|

|

|

$560 |

$910 |

|

|

|

|

$650 |

$1,820 |

$2,080 |

$1,820 |

$2,080 |

$3,437 |

$2,778 |

$1,675 |

$1,675 |

$1,560 |

$1,680 |

$5,532 |

$2,700 |

$2,080 |

$2,470 |

|

|

|

CNC Machine Labor |

|

|

$0 |

|

|

|

|

|

|

|

|

|

Remove Boss |

|

$0 |

|

Modify |

|

|

2 |

30 |

50 |

|

|

|

|

|

|

$560 |

$910 |

|

|

|

|

$650 |

$1,820 |

$2,080 |

$1,820 |

$2,080 |

$3,437 |

$2,778 |

$1,675 |

$1,675 |

$1,560 |

$1,680 |

$5,532 |

$2,700 |

$2,080 |

$2,470 |

|

|

|

Conv. Machine Labor |

|

|

$0 |

|

ECI # |

|

Reason for Change |

|

|

|

|

|

|

Add (w/ Sleeve) |

|

$0 |

|

|

|

|

3 |

50 |

100 |

|

|

|

|

|

|

$1,120 |

$1,365 |

|

|

|

|

$1,300 |

$2,730 |

$3,120 |

$2,730 |

$3,120 |

$4,096 |

$3,108 |

$2,500 |

$2,500 |

$2,340 |

$2,500 |

$6,849 |

$3,750 |

$3,120 |

$3,640 |

|

|

|

Welding Labor |

|

|

$0 |

|

Modification Area / size |

|

|

|

|

|

|

Remove (w/ Sleeve) |

|

$0 |

|

Diamond Polish |

$0 |

|

4 |

100 |

200 |

|

|

|

|

|

|

$1,960 |

$2,048 |

|

|

|

|

$2,470 |

$2,730 |

$3,120 |

$2,730 |

$3,120 |

$4,096 |

$3,108 |

$2,500 |

$2,500 |

$2,340 |

$2,500 |

$6,849 |

$3,750 |

$3,120 |

$3,640 |

|

|

|

Assembly Labor - Mechanical |

|

|

$0 |

|

Item |

$/Hr. |

Hours: |

Total: |

Item |

$/Hr. |

Hours: |

Total: |

|

|

|

|

|

|

Clip Tower |

|

|

|

|

Texture Repair/Change |

$0 |

|

5 |

200 |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

$3,458 |

$3,900 |

$4,420 |

$3,900 |

$4,420 |

$5,413 |

$3,766 |

$5,000 |

$5,000 |

$4,420 |

$4,940 |

$9,483 |

$7,000 |

$4,940 |

$5,460 |

|

|

|

Assembly Labor - Electrical |

|

|

$0 |

|

Design Cost |

|

|

$0 |

Bench |

|

|

$0 |

|

|

|

|

|

|

|

Add |

|

$0 |

|

Engraving per line |

$0 |

|

6 |

Add per mm |

0 |

|

|

|

|

|

|

$8.40 |

$6.83 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Assembly Labor - Pneumatic/Hydraulic |

|

|

$0 |

|

Material: |

|

|

$0 |

Heat Treat |

|

|

$0 |

|

|

|

|

|

|

|

Remove |

|

$0 |

|

|

|

|

7 |

0 |

2500 |

|

|

|

|

|

|

|

|

$1,300 |

$1,820 |

$1,300 |

$1,820 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$1,106 |

$664 |

|

Material - Raw |

|

$0 |

|

Programming. |

|

|

$0 |

Polishing |

|

|

$0 |

|

|

|

|

|

|

Rib Change |

|

|

|

Max |

Row |

Max |

Row |

8 |

2500 |

40000 |

|

|

|

|

|

|

|

|

$1,820 |

$2,600 |

$1,820 |

$2,600 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$2,212 |

$1,327 |

|

Material - Purchased Components |

|

$0 |

|

Dis-Assembly |

|

|

$0 |

Coating |

|

|

$0 |

|

|

|

|

|

ECI Cost Estimate |

|

New / Heighten |

|

$0 |

0 |

0 |

0 |

0 |

9 |

40000 |

1000000 |

|

|

|

|

|

|

|

|

$2,600 |

$3,770 |

$2,600 |

$3,770 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$4,424 |

$2,654 |

|

Material - Electrical |

|

$0 |

|

CNC Machining |

|

|

$0 |

Assembly |

|

|

$0 |

|

|

|

|

|

$0.00 |

|

Remove / Shorten |

|

$0 |

0 |

0 |

0 |

0 |

10 |

Add per mm2 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heat Treat |

|

$0 |

|

Conv. Machining |

|

|

$0 |

Tryout & Tune |

|

|

$0 |

|

|

|

|

|

|

Part Surface / Thickness Change |

|

|

|

Area |

Row |

Area |

Row |

|

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Coating |

|

|

Type: |

|

$/Kg |

|

|

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total Cost |

$0 |

|

|

|

|

|

|

|

Cavity (Machining) |

|

$0 |

0 |

0 |

0 |

0 |

|

|

|

$0 |

$0 |

$0 |

$0 |

$0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tryout Labor Cost |

|

|

$0 |

|

Change items (List sizes in mm, areas in mm2, and diameters in mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cavity (Weld & Machining) |

|

$0 |

0 |

0 |

0 |

0 |

|

Mechanical Slide / Lifter |

|

|

Area |

Row |

Area |

Row |

|

Hydraulic Slide |

|

|

Area |

Row |

Area |

Row |

Insert |

|

Area |

Row |

Area |

Row |

|

|

|

|

|

|

|

|

|

|

|

CMM Labor - (Layout) |

|

|

$0 |

|

List Change Item |

Change Content |

Size /Area |

Qty |

Change Content |

Size /Area |

Qty |

|

|

|

|

|

Core (Machining) |

|

$0 |

0 |

0 |

0 |

0 |

|

New Slide |

|

$0 |

0 |

0 |

0 |

0 |

|

New Slide |

|

$0 |

0 |

0 |

0 |

0 |

New |

$0 |

0 |

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

Tryout Material Cost |

|

|

$0 |

|

L |

W |

L |

W |

|

|

|

|

|

Core (Weld & Machining) |

|

$0 |

0 |

0 |

0 |

0 |

|

New Lifter |

|

$0 |

0 |

0 |

0 |

0 |

|

Eliminate Slide |

|

$0 |

0 |

0 |

0 |

0 |

Modify |

$0 |

0 |

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

Packaging |

|

|

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Add Radius (Non PL Mod) |

|

$0 |

0 |

0 |

0 |

0 |

|

Eliminate Slide |

|

$0 |

0 |

0 |

0 |

0 |

|

Lifter (Machining) |

|

$0 |

0 |

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Form Analysis |

|

|

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parting Line Change |

|

|

|

|

|

|

|

|

Eliminate Lifter |

|

$0 |

0 |

0 |

0 |

0 |

|

Lifter (Weld+Machine) |

|

$0 |

0 |

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Transport cost (Tool builder to Production location) |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cavity (Machining) |

|

$0 |

0 |

0 |

0 |

0 |

|

Lifter/Slide (Machining) |

|

$0 |

0 |

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Other: |

|

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cavity (Weld & Machining) |

|

$0 |

0 |

0 |

0 |

0 |

|

Lifter/Slide (Weld+Machine) |

|

$0 |

0 |

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Total |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Core (Machining) |

|

$0 |

0 |

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Core (Weld & Machining) |

|

$0 |

0 |

0 |

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Timing: (If ECI, list latest ECI change timing) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lead-time Quoted (weeks after K.O.) |

|

|

|

|

|

|

|

|

|

|

Base Tool |

ECI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1st Off Parts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sample Parts (tuned parts) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Part Approval (all documentation) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Production Ready |

|

|

|

|

|

|

|

|

|

|

|

|

|

Modification by: |

|

Vendor Address: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

36-38-40-45-68 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For Internal Use Only: |

|

|

|

|

|

|

|

TC |

|

TT |

|

EC |

|

Completed By: |

|

|

|

|

|

Aisin Asset # |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BB |

|

36-38-40-45-68 |

|

|

|

|

|

TR |

|

LT |

|

|

|

Date: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| IV. Injection Tooling Detail |

|

|

|

|

|

|

|

|

|

|

|

Supplier: |

|

|

|

|

Item #: |

|

|

|

|

Aisin Part #: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Material |

Part Material class |

|

|

|

|

|

|

|

|

|

Currency |

Tool Purchase currency |

|

|

|

|

|

|

|

|

|

Process |

Cavities |

|

|

|

|

|

|

|

|

|

Mold Plate |

|

|

|

|

|

|

|

|

|

|

|

|

Die Area |

0 |

|

|

|

Row # |

|

Row # |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Specific Material / Grade |

|

|

|

|

|

|

|

|

|

Exchange Rate Used / USD |

|

|

|

|

|

|

|

|

|

Family Tool |

|

|

|

|

|

|

|

|

# of Tool Sets Quoted |

|

|

|

|

|

|

This should only be greater than one if additional tool sets are need to meet capacity

1 |

|

|

|

|

|

|

|

Required tonnage |

#N/A |

#N/A |

|

|

1 |

|

0 |

41 |

0 |

81 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Date paid: |

|

|

|

|

|

|

|

|

|

Injection machine rated tonnage |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shipping Column |

|

|

|

|

2 |

|

0 |

42 |

0 |

82 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

0 |

43 |

0 |

83 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Set #1 |

Set #2 |

Set #3 |

Set #4 |

|

|

|

|

|

|

|

Yes |

Hot |

Std. |

|

|

4 |

|

0 |

44 |

0 |

84 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Size of (in mm) |

Length (mm) |

Width (mm) |

Depth / Line of Draw (mm) |

Tool Material |

Quantity |

|

|

|

|

|

|

|

Size (mm) |

Qty |

Size (mm) |

Qty |

Size (mm) |

Qty |

Size (mm) |

Qty |

|

|

|

|

|

|

|

No |

Cold |

Valve |

|

|

5 |

|

0 |

45 |

0 |

85 |

0 |

|

|

Slides |

Lifters |

|

|

|

|

|

|

|

|

|

|

Part Dimension / Mold depth |

|

|

|

|

|

|

Mechanical Slides |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

0 |

46 |

0 |

86 |

0 |

|

Row |

Mechanical |

Hydraulic |

Straight |

Angle |

|

|

|

|

|

|

|

|

|

|

A Plate (mm) |

|

|

|

|

|

|

Hydraulic Slides |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Row number |

|

0 |

|

|

7 |

|

0 |

47 |

0 |