184x Filetype XLS File size 0.11 MB Source: fyi.extension.wisc.edu

Sheet 1: MACHCOST

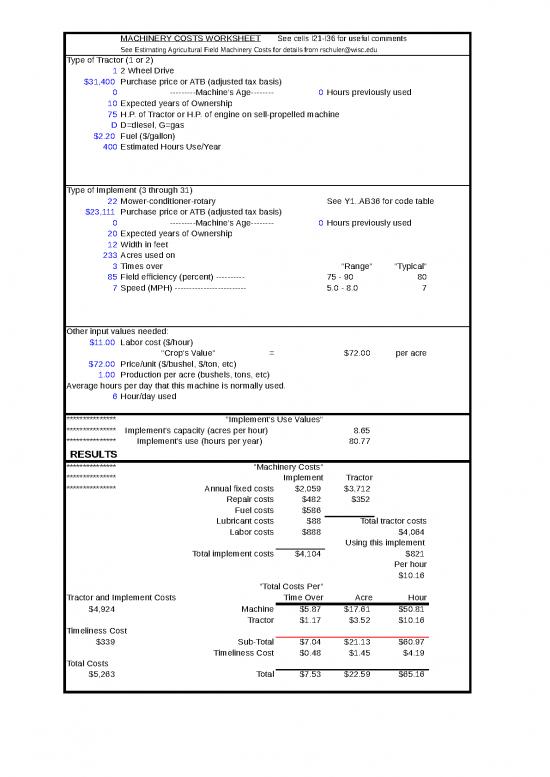

| MACHINERY COSTS WORKSHEET | See cells I21-I36 for useful comments | 1 | 45.57 | 51.19 | 57.92 | 54.61 | To print this table and guide, print area Y1..AB36 | ||||||||||||||||||||||||||||||

| See Estimating Agricultural Field Machinery Costs for details from rschuler@wisc.edu | 2 | 28.29 | 31.52 | 34.14 | 32.88 | Strike the "Home" key to get to the start of this program. | |||||||||||||||||||||||||||||||

| Type of Tractor (1 or 2) | 3 | 22.24 | 24.51 | 25.82 | 25.21 | Machine | Code | Timeliness | Hours | % of Price | RF1 | RF2 | |||||||||||||||||||||||||

| 1 | 2 Wheel Drive | 4 | 19.01 | 20.70 | 21.40 | 21.08 | 1 | Tractor, 2 wheel drive | = | 1 | 1 | N.A. | N.A. | N.A. | N.A. | 0 | 12000 | 100 | 0.007 | 2 | |||||||||||||||||

| $31,400 | Purchase price or ATB (adjusted tax basis) | 5 | 16.92 | 18.21 | 18.56 | 18.41 | 2 | Tractor, 4 wheel drive | = | 2 | 1 | N.A. | N.A. | N.A. | N.A. | 0 | 16000 | 80 | 0.003 | 2 | |||||||||||||||||

| 0 | ---------Machine's Age-------- | 0 | Hours previously used | 6 | 15.41 | 16.38 | 16.52 | 16.47 | 3 | Moldboard plow | = | 3 | 4 | 70 - 90 | 85 | 3.0 - 6.0 | 4.5 | 0 | 2000 | 100 | 0.29 | 1.8 | |||||||||||||||

| 10 | Expected years of Ownership | 7 | 14.25 | 14.96 | 14.97 | 14.98 | 4 | Heavy Duty Disk | = | 4 | 4 | 70 - 90 | 85 | 3.5 - 6.0 | 4.5 | 0 | 2000 | 60 | 0.18 | 1.7 | |||||||||||||||||

| 75 | H.P. of Tractor or H.P. of engine on sell-propelled machine | 8 | 13.30 | 13.80 | 13.72 | 13.77 | 5 | Tandem Disk Harrow | = | 5 | 4 | 70 - 90 | 80 | 4.0 - 7.0 | 6 | 0 | 2000 | 60 | 0.18 | 1.7 | |||||||||||||||||

| D | D=diesel, G=gas | 9 | 12.51 | 12.83 | 12.68 | 12.76 | 6 | Chisel Plows | = | 6 | 4 | 70 - 90 | 85 | 4.0 - 6.5 | 5 | 0 | 2000 | 75 | 0.28 | 1.4 | |||||||||||||||||

| $2.20 | Fuel ($/gallon) | 10 | 11.82 | 11.99 | 11.81 | 11.90 | 7 | Subsoiler | = | 7 | 4 | 70 - 90 | 85 | 4.0 - 6.5 | 5 | 0 | 2000 | 75 | 0.28 | 1.4 | |||||||||||||||||

| 400 | Estimated Hours Use/Year | 11 | 11.22 | 11.26 | 11.05 | 11.16 | 8 | Field Cultivator | = | 8 | 4 | 70 - 90 | 85 | 5.0 - 8.0 | 7 | 0 | 2000 | 70 | 0.27 | 1.4 | |||||||||||||||||

| 12 | 10.68 | 10.61 | 10.38 | 10.50 | 9 | Spring Tooth Harrow | = | 9 | 4 | 70 - 90 | 85 | 5.0 - 8.0 | 7 | 0 | 2000 | 70 | 0.27 | 1.4 | |||||||||||||||||||

| 13 | 10.20 | 10.04 | 9.79 | 9.91 | 10 | Roller-packer | = | 10 | 4 | 70 - 90 | 85 | 4.5 - 7.5 | 6 | 0 | 2000 | 40 | 0.16 | 1.3 | |||||||||||||||||||

| 14 | 9.76 | 9.51 | 9.26 | 9.38 | 11 | Mulcher-packers | = | 11 | 4 | 70 - 90 | 80 | 4.0 - 6.0 | 5 | 0 | 2000 | 40 | 0.16 | 1.3 | |||||||||||||||||||

| Type of Implement (3 through 31) | 15 | 9.36 | 9.04 | 8.79 | 8.91 | 12 | Rotary Hoe | = | 12 | 4 | 70 - 85 | 80 | 5.0 -14.0 | 12 | 0.028 | 2000 | 60 | 0.23 | 1.4 | ||||||||||||||||||

| 22 | Mower-conditioner-rotary | See Y1..AB36 for code table | 13 | Row Crop Cultivators | = | 13 | 4 | 70 - 90 | 80 | 3.0 - 7.0 | 5 | 0.011 | 2000 | 80 | 0.17 | 2.2 | |||||||||||||||||||||

| $23,111 | Purchase price or ATB (adjusted tax basis) | Table 4 (annual average fixed costs) | 14 | Rotary Tiller | = | 14 | 4 | 70 - 90 | 85 | 1.0 - 4.5 | 3 | 0.011 | 1500 | 80 | 0.36 | 2 | |||||||||||||||||||||

| 0 | ---------Machine's Age-------- | 0 | Hours previously used | 15 | Row Crop Planter (No-till) | = | 15 | 4 | 50 - 75 | 65 | 4.0 - 7.0 | 5.5 | 0.005 | 1500 | 75 | 0.32 | 2.1 | ||||||||||||||||||||

| 20 | Expected years of Ownership | 16 | Row Crop Planter (conventional) | = | 16 | 4 | 50 - 80 | 70 | 4.0 - 7.0 | 5 | 0.005 | 1500 | 75 | 0.32 | 2.1 | ||||||||||||||||||||||

| 12 | Width in feet | 17 | Grain Drill | = | 17 | 4 | 55 - 80 | 70 | 4.0 - 7.0 | 5 | 0.012 | 1500 | 75 | 0.32 | 2.1 | ||||||||||||||||||||||

| 233 | Acres used on | COMMENTS: | 18 | Corn Picker or Sheller | = | 18 | 3 | 60 - 75 | 65 | 2.0 - 5.0 | 2.5 | 0.003 | 2000 | 70 | 0.14 | 2.3 | |||||||||||||||||||||

| 3 | Times over | "Range" | "Typical" | 1. The most recent (2005) machinery data from the American Society of Agricultural Engineer | 19 | Combines (pull-type) | = | 19 | 2 | 60 - 75 | 65 | 2.0 - 5.0 | 5 | 0.003 | 2000 | 60 | 0.12 | 2.3 | |||||||||||||||||||

| 85 | Field efficiency (percent) ---------- | 75 - 90 | 80 | (as of July,2005 it is called American Society of Agricultural and Biological Engineers) | 20 | Combine (self-propelled) | = | 20 | 2 | 65 - 80 | 70 | 2.0 - 5.0 | 3 | 0.003 | 3000 | 40 | 0.04 | 2.1 | |||||||||||||||||||

| 7 | Speed (MPH) ------------------------- | 5.0 - 8.0 | 7 | 2.User can taylor the analysis to their situation inputting many data values i.e. fuel price, | 21 | Mower-conditioner-sickle | = | 21 | 4 | 75 - 85 | 80 | 3.0 - 6.0 | 5 | 0.018 | 2500 | 80 | 0.18 | 1.6 | |||||||||||||||||||

| equipment purchase price, acres, and forward speed. | 22 | Mower-conditioner-rotary | = | 22 | 4 | 75 - 90 | 80 | 5.0 - 8.0 | 7 | 0.018 | 2500 | 100 | 0.16 | 2 | |||||||||||||||||||||||

| 3. If a tractor is used for multiple purposes, the hourly tractor costs are calculated and | 23 | Mower-conditioner (self-propelled) | = | 23 | 2 | 70 - 85 | 80 | 3.0 - 8.0 | 5 | 0.018 | 3000 | 55 | 0.06 | 2 | |||||||||||||||||||||||

| the tractor costs for a tractor powered machine is determined for the number of hours | 24 | Side Delivery Rake | = | 24 | 3 | 70 - 90 | 80 | 6.5 - 13.0 | 10 | 0.018 | 2500 | 60 | 0.17 | 1.4 | |||||||||||||||||||||||

| Other input values needed: | used for the operation times the hourly tractor costs. | 25 | Sm. Rect.Baler | = | 25 | 3 | 60 - 85 | 75 | 2.5 - 6.0 | 4 | 0.018 | 2000 | 80 | 0.23 | 1.8 | ||||||||||||||||||||||

| $11.00 | Labor cost ($/hour) | 4. The cost results are located in cells A1... F60. This print area has already been | 26 | Big Bale Rect Baler | = | 26 | 3 | 70 - 90 | 80 | 5.0 - 8.0 | 5 | 0.018 | 3000 | 75 | 0.1 | 1.8 | |||||||||||||||||||||

| "Crop's Value" = | $72.00 | per acre | established for getting a hard copy of results. | 27 | Large Round Baler | = | 27 | 3 | 55 - 75 | 65 | 3.0 - 8.0 | 5 | 0.018 | 1500 | 90 | 0.43 | 1.8 | ||||||||||||||||||||

| $72.00 | Price/unit ($/bushel, $/ton, etc) | 5. The machinery code numbers are located in area Y1....AB36, also noted in the | 28 | Forage Chopper (pull-type) | = | 28 | 3 | 60 - 85 | 70 | 1.5 - 5.0 | 3 | 0.018 | 2500 | 65 | 0.15 | 1.6 | |||||||||||||||||||||

| 1.00 | Production per acre (bushels, tons, etc) | spreadsheet in line 16 of results. | 29 | Forage Chopper (Self- propelled) | = | 29 | 2 | 60 - 85 | 70 | 1.5 - 6.0 | 3.5 | 0.018 | 4000 | 50 | 0.03 | 2 | |||||||||||||||||||||

| Average hours per day that this machine is normally used. | 6. If you use a machine that has been used beyond the wear-out life, you will get a | 30 | Fertilizer Spreader | = | 30 | 3 | 60 - 80 | 70 | 5.0 - 10.0 | 7 | 0.018 | 1200 | 80 | 0.63 | 1.3 | ||||||||||||||||||||||

| 6 | Hour/day used | warning and machine costs will be large because the repair costs are determined | 31 | Boom Sprayers | = | 31 | 3 | 50 - 80 | 65 | 3.0 - 7.0 | 6.5 | 0.011 | 1500 | 70 | 0.41 | 1.3 | |||||||||||||||||||||

| using a formula with a exponential term. Hours will need to be adjusted to get realistic values. | 32 | Blower, forage | = | 32 | 3 | N.A. | N.A. | 0 | 1500 | 45 | 0.22 | 1.8 | |||||||||||||||||||||||||

| * | "Implement's Use Values" | 7. For self propelled equipment use a tractor purchase price of zero. | 33 | Wagons | = | 33 | 3 | N.A. | N.A. | 0 | 2000 | 50 | 0.16 | 1.3 | |||||||||||||||||||||||

| * | Implement's capacity (acres per hour) | 8.65 | |||||||||||||||||||||||||||||||||||

| * | Implement's use (hours per year) | 80.77 | |||||||||||||||||||||||||||||||||||

| RESULTS | |||||||||||||||||||||||||||||||||||||

| * | "Machinery Costs" | ||||||||||||||||||||||||||||||||||||

| * | Implement | Tractor | |||||||||||||||||||||||||||||||||||

| * | Annual fixed costs | $2,059 | $3,712 | After striking the <Home> key, enter the values associated with | |||||||||||||||||||||||||||||||||

| Repair costs | $482 | $352 | your tractor and/or machine in the cells that are brighter. You can not | ||||||||||||||||||||||||||||||||||

| Fuel costs | $586 | not enter values in the other cells. The program will not let you. | |||||||||||||||||||||||||||||||||||

| Lubricant costs | $88 | Total tractor costs | |||||||||||||||||||||||||||||||||||

| Labor costs | $888 | $4,064 | |||||||||||||||||||||||||||||||||||

| Using this implement | |||||||||||||||||||||||||||||||||||||

| Total implement costs | $4,104 | $821 | |||||||||||||||||||||||||||||||||||

| Per hour | The results start on line 36. You can study them and the print | ||||||||||||||||||||||||||||||||||||

| $10.16 | those results (using Alt R) or change the values entered to get | ||||||||||||||||||||||||||||||||||||

| "Total Costs Per" | another analysis; or both. Remember: to get to the start of the | ||||||||||||||||||||||||||||||||||||

| Tractor and Implement Costs | Time Over | Acre | Hour | program just strike the <Home> key. | |||||||||||||||||||||||||||||||||

| $4,924 | Machine | $5.87 | $17.61 | $50.81 | |||||||||||||||||||||||||||||||||

| Tractor | $1.17 | $3.52 | $10.16 | ||||||||||||||||||||||||||||||||||

| Timeliness Cost | |||||||||||||||||||||||||||||||||||||

| $339 | Sub-Total | $7.04 | $21.13 | $60.97 | |||||||||||||||||||||||||||||||||

| Timeliness Cost | $0.48 | $1.45 | $4.19 | ||||||||||||||||||||||||||||||||||

| Total Costs | |||||||||||||||||||||||||||||||||||||

| $5,263 | Total | $7.53 | $22.59 | $65.16 | |||||||||||||||||||||||||||||||||

| \G | |||||||||||||||||||||||||||||||||||||

| /pprlist~gpq | |||||||||||||||||||||||||||||||||||||

| \R | |||||||||||||||||||||||||||||||||||||

| /pprresults~gq | |||||||||||||||||||||||||||||||||||||

| 11.8215487248145 | tractor fixed cost factor | ||||||||||||||||||||||||||||||||||||

| 8.90797700509622 | machine fixed cost factor | RF1 | RF2 | ||||||||||||||||||||||||||||||||||

| tractor repair cost factors | 0.007 | 2 | |||||||||||||||||||||||||||||||||||

| machine repair cost factors | 0.16 | 2 | |||||||||||||||||||||||||||||||||||

| 1 | tractor fixed cost column | ||||||||||||||||||||||||||||||||||||

| 4 | machine fixed cost column | ||||||||||||||||||||||||||||||||||||

| 0.044 | tractor fuel cost factor | ||||||||||||||||||||||||||||||||||||

| For calculating repair costs of used equipment | |||||||||||||||||||||||||||||||||||||

| $31,400 | tractor's value new (estimate) | 1 | |||||||||||||||||||||||||||||||||||

| $23,111 | machine's value new (estimate) | 1 | |||||||||||||||||||||||||||||||||||

| Annual fixed costs in per cent of list price by machine catagory | |||||||||||||||||||||||||||||||||||||

| Table 3 | Combines | Forage Choppers | Mowers | ||||||||||||||||||||||||||||||||||

| Age | Tractors | S.P. Windrowers | Balers, blowers | Tillage | |||||||||||||||||||||||||||||||||

| - | - | - | - | - | - | - | |||||||||||||||||||||||||||||||

| 1 | 45.57 | 51.19 | 57.92 | 54.61 | |||||||||||||||||||||||||||||||||

| 2 | 11.01 | 11.85 | 10.37 | 11.15 | |||||||||||||||||||||||||||||||||

| 3 | 10.13 | 10.49 | 9.18 | 9.86 | |||||||||||||||||||||||||||||||||

| 4 | 9.32 | 9.28 | 8.12 | 8.71 | |||||||||||||||||||||||||||||||||

| 5 | 8.57 | 8.22 | 7.19 | 7.70 | |||||||||||||||||||||||||||||||||

| 6 | 7.89 | 7.27 | 6.36 | 6.81 | |||||||||||||||||||||||||||||||||

| 7 | 7.26 | 6.43 | 5.63 | 6.02 | |||||||||||||||||||||||||||||||||

| 8 | 6.68 | 5.69 | 4.98 | 5.32 | |||||||||||||||||||||||||||||||||

| 9 | 6.14 | 5.04 | 4.41 | 4.70 | |||||||||||||||||||||||||||||||||

| 10 | 5.65 | 4.46 | 3.90 | 4.16 | |||||||||||||||||||||||||||||||||

| 11 | 5.20 | 3.95 | 3.45 | 3.68 | |||||||||||||||||||||||||||||||||

| 12 | 4.78 | 3.49 | 3.06 | 3.25 | |||||||||||||||||||||||||||||||||

| 13 | 4.40 | 3.09 | 2.71 | 2.87 | |||||||||||||||||||||||||||||||||

| 14 | 4.05 | 2.74 | 2.39 | 2.54 | |||||||||||||||||||||||||||||||||

| 15 | 3.72 | 2.42 | 2.12 | 2.24 | |||||||||||||||||||||||||||||||||

| 8 | Interest rate (percent) | 2 | percent for housing, ins, etc | ||||||||||||||||||||||||||||||||||

| 100.00 | 100.00 | 100.00 | 100.00 | ||||||||||||||||||||||||||||||||||

| 0 | 62.56 | 56.64 | 49.56 | 53.04 | |||||||||||||||||||||||||||||||||

| 0 | 57.56 | 50.13 | 43.86 | 46.89 | |||||||||||||||||||||||||||||||||

| 52.95 | 44.36 | 38.82 | 41.45 | ||||||||||||||||||||||||||||||||||

| Table 1 | 48.71 | 39.26 | 34.35 | 36.64 | |||||||||||||||||||||||||||||||||

| 44.82 | 34.75 | 30.40 | 32.39 | ||||||||||||||||||||||||||||||||||

| 41.23 | 30.75 | 26.91 | 28.63 | ||||||||||||||||||||||||||||||||||

| 37.93 | 27.21 | 23.81 | 25.31 | ||||||||||||||||||||||||||||||||||

| 34.90 | 24.08 | 21.07 | 22.38 | ||||||||||||||||||||||||||||||||||

| 32.11 | 21.31 | 18.65 | 19.78 | ||||||||||||||||||||||||||||||||||

| 29.54 | 18.86 | 16.51 | 17.49 | ||||||||||||||||||||||||||||||||||

| 27.18 | 16.69 | 14.61 | 15.46 | ||||||||||||||||||||||||||||||||||

| 25.00 | 14.77 | 12.93 | 13.66 | ||||||||||||||||||||||||||||||||||

| 23.00 | 13.08 | 11.44 | 12.08 | ||||||||||||||||||||||||||||||||||

| 21.16 | 11.57 | 10.12 | 10.68 | ||||||||||||||||||||||||||||||||||

| 19.47 | 10.24 | 8.96 | 9.44 | ||||||||||||||||||||||||||||||||||

| 0 | 0 | 0 | 0 | ||||||||||||||||||||||||||||||||||

| 1 | 5 | 1 | 5 | ||||||||||||||||||||||||||||||||||

| 2 | 9 | 2 | 9 | ||||||||||||||||||||||||||||||||||

| 3 | 12 | 3 | 12 | ||||||||||||||||||||||||||||||||||

| 4 | 14 | 4 | 14 | Used equipment | |||||||||||||||||||||||||||||||||

| 5 | 15 | 5 | 15 | adjustment factors | |||||||||||||||||||||||||||||||||

| 6 | 16 | 6 | 16 | ||||||||||||||||||||||||||||||||||

| 7 | 17 | 7 | 17 | ||||||||||||||||||||||||||||||||||

| 8 | 18 | 8 | 18 | ||||||||||||||||||||||||||||||||||

| 9 | 19 | 9 | 19 | ||||||||||||||||||||||||||||||||||

| 10 | 20 | 10 | 20 | ||||||||||||||||||||||||||||||||||

| 11 | 21 | 11 | 21 | ||||||||||||||||||||||||||||||||||

| 12 | 22 | 12 | 22 | ||||||||||||||||||||||||||||||||||

| 13 | 23 | 13 | 23 | ||||||||||||||||||||||||||||||||||

| 14 | 24 | 14 | 24 | ||||||||||||||||||||||||||||||||||

| 15 | 25 | 15 | 25 | ||||||||||||||||||||||||||||||||||

| 16 | 26 | 16 | 26 | ||||||||||||||||||||||||||||||||||

| 17 | 27 | 17 | 27 | ||||||||||||||||||||||||||||||||||

| 18 | 28 | 18 | 28 | ||||||||||||||||||||||||||||||||||

| 19 | 29 | 19 | 29 | ||||||||||||||||||||||||||||||||||

| 20 | 30 | 20 | 30 |

| COMMENTS: |

| 1. The most recent (2005) machinery data from the American Society of Agricultural Engineer |

| (as of July,2005 it is called American Society of Agricultural and Biological Engineers) |

| 2.User can taylor the analysis to their situation inputting many data values i.e. fuel price, |

| equipment purchase price, acres, and forward speed. |

| 3. If a tractor is used for multiple purposes, the hourly tractor costs are calculated and |

| the tractor costs for a tractor powered machine is determined for the number of hours |

| used for the operation times the hourly tractor costs. |

| 4. The cost results are located in cells A1... F60. This print area has already been |

| established for getting a hard copy of results. |

| 5. The machinery code numbers are located in area Y1....AB36, also noted in the |

| spreadsheet in line 16 of results. |

| 6. If you use a machine that has been used beyond the wear-out life, you will get a |

| warning and machine costs will be large because the repair costs are determined |

| using a formula with a exponential term. Hours will need to be adjusted to get realistic values. |

| 7. For self propelled equipment use a tractor purchase price of zero. |

no reviews yet

Please Login to review.