322x Filetype XLSX File size 0.06 MB Source: www.volvogroup.com

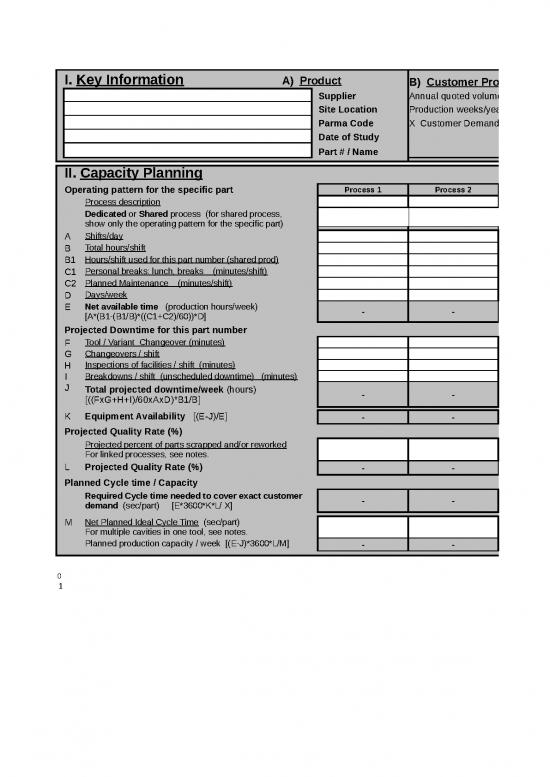

Sheet 1: Initial Capacity Assessm. Sheet

| I. Key Information A) Product | B) Customer Production | |||||||||||

| Supplier | Annual quoted volume (RFQ volume) | Method | Date | Description | ||||||||

| Site Location | Production weeks/year (at customer) | |||||||||||

| Parma Code | X Customer Demand / Week | - | ||||||||||

| Date of Study | ||||||||||||

| Part # / Name | ||||||||||||

| II. Capacity Planning | ||||||||||||

| Operating pattern for the specific part | Process 1 | Process 2 | Process 3 | Process 4 | Process 5 | Process 6 | Process 7 | |||||

| Process description | ||||||||||||

| Dedicated or Shared process (for shared process, show only the operating pattern for the specific part) |

2 | 1 | 1 | 1 | 2 | 2 | 2 | |||||

| A | Shifts/day | |||||||||||

| B | Total hours/shift | |||||||||||

| B1 | Hours/shift used for this part number (shared prod) | |||||||||||

| C1 | Personal breaks: lunch, breaks (minutes/shift) | |||||||||||

| C2 | Planned Maintenance (minutes/shift) | |||||||||||

| D | Days/week | |||||||||||

| E | Net available time (production hours/week) [A*(B1-(B1/B)*((C1+C2)/60))*D] |

- | - | - | - | - | - | - | ||||

| Projected Downtime for this part number | ||||||||||||

| F | Tool / Variant Changeover (minutes) | |||||||||||

| G | Changeovers / shift | |||||||||||

| H | Inspections of facilities / shift (minutes) | |||||||||||

| I | Breakdowns / shift (unscheduled downtime) (minutes) | |||||||||||

| J | Total projected downtime/week (hours) [((FxG+H+I)/60xAxD)*B1/B] | - | - | - | - | - | - | - | ||||

| K | Equipment Availability [(E-J)/E] | - | - | - | - | - | - | - | ||||

| Projected Quality Rate (%) | ||||||||||||

| Projected percent of parts scrapped and/or reworked For linked processes, see notes. |

||||||||||||

| L | Projected Quality Rate (%) | - | - | - | - | - | - | - | ||||

| Planned Cycle time / Capacity | ||||||||||||

| Required Cycle time needed to cover exact customer demand (sec/part) [E*3600*K*L/ X] | - | - | - | - | - | - | - | |||||

| M | Net Planned Ideal Cycle Time (sec/part) For multiple cavities in one tool, see notes. |

|||||||||||

| Planned production capacity / week [(E-J)*3600*L/M] | - | - | - | - | - | - | - | |||||

| 0 | DEDICATED | |||||||||||

| 1 | SHARED | |||||||||||

no reviews yet

Please Login to review.