248x Filetype XLSX File size 0.66 MB Source: www.conmet.com

Sheet 1: Cover

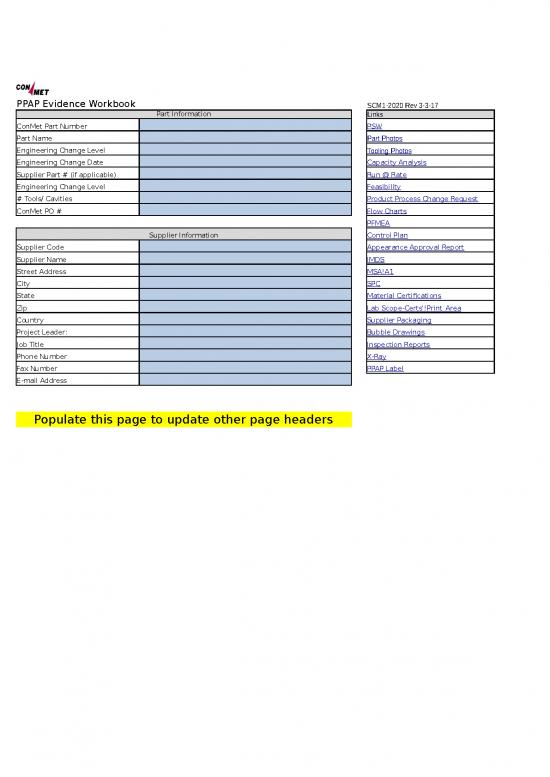

| PPAP Evidence Workbook | SCM1-2020 Rev 3-3-17 | |||

| Part Information | Links | |||

| ConMet Part Number | PSW | |||

| Part Name | Part Photos | |||

| Engineering Change Level | Tooling Photos | |||

| Engineering Change Date | Capacity Analysis | |||

| Supplier Part # (if applicable) | Run @ Rate | |||

| Engineering Change Level | Feasibility | |||

| # Tools/ Cavities | Product Process Change Request | |||

| ConMet PO # | Flow Charts | |||

| PFMEA | ||||

| Supplier Information | Control Plan | |||

| Supplier Code | Appearance Approval Report | |||

| Supplier Name | IMDS | |||

| Street Address | MSA!A1 | |||

| City | SPC | |||

| State | Material Certifications | |||

| Zip | Lab Scope-Certs'!Print_Area | |||

| Country | Supplier Packaging | |||

| Project Leader: | Bubble Drawings | |||

| Job Title | Inspection Reports | |||

| Phone Number | X-Ray | |||

| Fax Number | PPAP Label | |||

| E-mail Address | ||||

| Populate this page to update other page headers | ||||

| All necessary requirements, including drawings, specifications, regulations, ConMet and OEM customer requirements must be passed down the supply chain to ensure compliance to product requirements. | ||||

| Cover!A1 | ||||||||||||||||||||||||||

| Part Name: | 0 | ConMet Part Number: | 0 | |||||||||||||||||||||||

| Safety and/or Government Regulations? | Engineering Drawing Revision Level: | 0 | Dated: | |||||||||||||||||||||||

| Checking Aid # | Checking Aid Engineering Change Level: | Dated: | ||||||||||||||||||||||||

| Additional Engineering Changes | Dated: | |||||||||||||||||||||||||

| Shown on Drawing # | Purchase Order #: | Weight (kg): | ||||||||||||||||||||||||

| SUPPLIER MANUFACTURING INFORMATION | SUBMISSION INFORMATION | |||||||||||||||||||||||||

| 0 | 0 | Consolidated Metco | ||||||||||||||||||||||||

| Supplier Company Name | Supplier Vendor Number | Customer Name: | ||||||||||||||||||||||||

| 0 | ||||||||||||||||||||||||||

| Street Address | ConMet Manufacturing Locations | |||||||||||||||||||||||||

| 0 | 0 | 0 | 0 | |||||||||||||||||||||||

| City | State | Zip | Country | ConMet Sourcing Manager | Application | |||||||||||||||||||||

| Additional manufacturing sites | PPAP Due Date: | SOP Date: | ||||||||||||||||||||||||

| Does this part utilize ConMet owned tooling? Is it properly identified? | If yes, P.O. # | |||||||||||||||||||||||||

| Material Reporting | ||||||||||||||||||||||||||

| Has the customer required Substances of Concern been reported? | IMDS # Number: | IMDS Approval Date: | ||||||||||||||||||||||||

| Does this part contain any restricted substances or require IMDS submission? | ||||||||||||||||||||||||||

| Are plastic or polymeric parts identified with appropriate ISO marking codes? | ||||||||||||||||||||||||||

| Has the yearly Layout been scheduled? | Supplier is responsible to schedule and submit yearly Layouts as required | |||||||||||||||||||||||||

| Has the yearly CQI certifications been Scheduled? | Supplier is responsible to schedule and submit yearly CQI Certs to ConMet | |||||||||||||||||||||||||

| REASON FOR SUBMISSION | ||||||||||||||||||||||||||

| Initial submission (New Parts and Part Number Changes) | New Supplier, New material or new source for existing material | |||||||||||||||||||||||||

| Engineering Change: New/Revised drawing or other specification | Change of supplier, material or non-equivalent materials/services | |||||||||||||||||||||||||

| Tooling: transfer, replacement (new), refurbishment, modified or additional | New process or a change in production process or method | |||||||||||||||||||||||||

| Correction of Non-conformance or discrepancy | Change of manufacturing location, sub-supplier or additional location | |||||||||||||||||||||||||

| Change to optional construction, material or component | Other - please specify blow: | |||||||||||||||||||||||||

| Yearly Submittal | ||||||||||||||||||||||||||

| Level 1 - Warrant only submitted to the customer (for designated appearance items submit Appearance Approval Report) | ||||||||||||||||||||||||||

| Level 2 - Warrant with product samples and limiting supporting data. (Applied to critical bulk product and simple changes) | ||||||||||||||||||||||||||

| Level 3 - Warrant with product samples and complete supporting data. | DEFAULT ConMet SUBMISSION LEVEL | |||||||||||||||||||||||||

| Level 4 - Warrant and other requirements as defined by ConMet. | ||||||||||||||||||||||||||

| Level 5 - Warrant with product samples and complete supporting data reviewed at supplier's manufacturing location. (Applied to parts requiring onsite review ) | ||||||||||||||||||||||||||

| SUBMISSION RESULTS | ||||||||||||||||||||||||||

| The results for: | dimensional measurements | material and functional tests | appearance criteria | statistical process package | ||||||||||||||||||||||

| All applicable statutory and regulatory requirements as and special product and process characteristivs have been passed down to suppliers. | ||||||||||||||||||||||||||

| Require their suppliers to do the same? | ||||||||||||||||||||||||||

| These results meet all drawing and specification requirements: | (If "NO" - Explanation Required in Explanation/comments section below ) | |||||||||||||||||||||||||

| Is this a multicavity tool? | Mold # | Production Process: | ||||||||||||||||||||||||

| DECLARATION | I affirm that the samples represented by this warrant are representative of our parts, have been made to the applicable Production Part Approval Process Manual 4th Edition requirements. I further warrant these samples were produced with the specified materials on regular production tooling with no operations other then the regular production process. |

|||||||||||||||||||||||||

| The data and samples were produced at the production rate of: | parts per | Hours | ||||||||||||||||||||||||

| Any deviations to this warrant submission are noted below in the explanation/comments section | ||||||||||||||||||||||||||

| EXPLANATION/ COMMENTS: | ||||||||||||||||||||||||||

| Type Name: | Job Title | Phone No. | ||||||||||||||||||||||||

| Supplier Signature: | Date | |||||||||||||||||||||||||

| For ConMet Use Only | ||||||||||||||||||||||||||

| Interim Disposition (if applicable): | Supplier must clearly identify all containers and manage expiration date or quantity limits of Interim Approval | |||||||||||||||||||||||||

| Scope of Interim Approval: | ||||||||||||||||||||||||||

| ConMet Signature: | Date: | |||||||||||||||||||||||||

| Final Part Warrant Disposition: | ||||||||||||||||||||||||||

| ConMet Signature: | ConMet PPAP Tracking # | |||||||||||||||||||||||||

| PPAP MASTER SAMPLE "PICTURE" DOCUMENTATION | Cover!A1 | |||||||||||

| Supplier Number | 0 | PART NUMBER: | 0 | |||||||||

| Supplier Name: | 0 | PART NAME: | 0 | |||||||||

| DESIGN RECORD CHANGE LEVEL: | 0 | |||||||||||

| Document the parts as a whole what they look like in the final state in which they are provided to ConMet | ||||||||||||

no reviews yet

Please Login to review.