285x Filetype XLS File size 0.04 MB Source: www.moresteam.com

Sheet 1: FMEA Template(simplified)

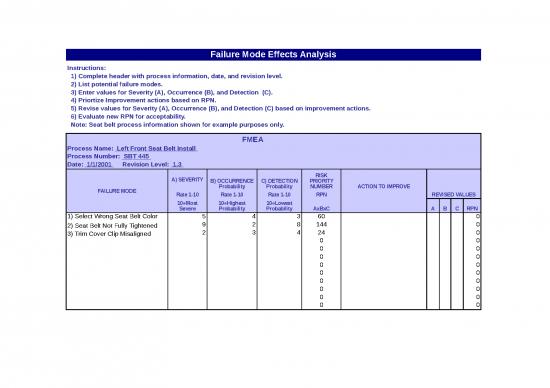

| Failure Mode Effects Analysis | |||||||||

| Instructions: | |||||||||

| 1) Complete header with process information, date, and revision level. | |||||||||

| 2) List potential failure modes. | |||||||||

| 3) Enter values for Severity (A), Occurrence (B), and Detection (C). | |||||||||

| 4) Priortize Improvement actions based on RPN. | |||||||||

| 5) Revise values for Severity (A), Occurrence (B), and Detection (C) based on improvement actions. | |||||||||

| 6) Evaluate new RPN for acceptability. | |||||||||

| Note: Seat belt process information shown for example purposes only. | |||||||||

| FMEA | |||||||||

| Process Name: Left Front Seat Belt Install | |||||||||

| Process Number: SBT 445 | |||||||||

| Date: 1/1/2001 Revision Level: 1.3 | |||||||||

| FAILURE MODE | A) SEVERITY | B) OCCURRENCE Probability | C) DETECTION Probability | RISK PRIORITY NUMBER | ACTION TO IMPROVE | REVISED VALUES | |||

| Rate 1-10 | Rate 1-10 | Rate 1-10 | RPN | ||||||

| 10=Most Severe | 10=Highest Probability | 10=Lowest Probability | AxBxC | A | B | C | RPN | ||

| 1) Select Wrong Seat Belt Color | 5 | 4 | 3 | 60 | 0 | ||||

| 2) Seat Belt Not Fully Tightened | 9 | 2 | 8 | 144 | 0 | ||||

| 3) Trim Cover Clip Misaligned | 2 | 3 | 4 | 24 | 0 | ||||

| 0 | 0 | ||||||||

| 0 | 0 | ||||||||

| 0 | 0 | ||||||||

| 0 | 0 | ||||||||

| 0 | 0 | ||||||||

| 0 | 0 | ||||||||

| 0 | 0 | ||||||||

| 0 | 0 | ||||||||

| 0 | 0 | ||||||||

| Potential Failure Mode Effects Analysis (Design FMEA) | |||||||||||||||||

| Instructions: | |||||||||||||||||

| 1) Complete header with design information, date, and revision level. | |||||||||||||||||

| 2) List potential failure modes. | |||||||||||||||||

| 3) Enter values for Severity (A), Occurrence (B), and Detection (C). | |||||||||||||||||

| 4) Priortize Improvement actions based on RPN. | |||||||||||||||||

| 5) Revise values for Severity (A), Occurrence (B), and Detection (C) based on improvement actions. | |||||||||||||||||

| 6) Evaluate new RPN for acceptability. | |||||||||||||||||

| FMEA | |||||||||||||||||

| ___ System | |||||||||||||||||

| ___ Subsystem | Design Responsibility _____________________ | FMEA Number_____________________________ | |||||||||||||||

| ___ Component ___________________________ | Key Date ________________________________ | Page ___ of ______ | |||||||||||||||

| Prepared by: ______________________________ | |||||||||||||||||

| FMEA Date (Orig) __________ (Rev) ___________ | |||||||||||||||||

| Core Team ___________________________________________________________________________ | |||||||||||||||||

| Item Function |

Potential Failure Mode | Potential Effect(s) of Failure | A) SEVERITY | Class | Potential Cause(s) / Mechanism (s) of Failure | B) OCCURRENCE Probability | Current Design Controls Prevention | Current Design Controls Detection | C) DETECTION Probability | RISK PRIORITY NUMBER | Recommended Action(s) | Responsibility and Target Completion Date | Action Results | ||||

| Rate 1-10 | Rate 1-10 | Rate 1-10 | RPN | ||||||||||||||

| 10=Most Severe | 10=Highest Probability | 10=Lowest Probability | AxBxC | Actions Taken | Sev | Occ | Det | RPN | |||||||||

| 0 | 0 | ||||||||||||||||

| 0 | 0 | ||||||||||||||||

| 0 | 0 | ||||||||||||||||

| 0 | 0 | ||||||||||||||||

| 0 | 0 | ||||||||||||||||

| 0 | 0 | ||||||||||||||||

| 0 | 0 | ||||||||||||||||

| 0 | 0 | ||||||||||||||||

| 0 | 0 | ||||||||||||||||

| 0 | 0 | ||||||||||||||||

| 0 | 0 | ||||||||||||||||

| 0 | 0 | ||||||||||||||||

no reviews yet

Please Login to review.