267x Filetype XLSX File size 0.28 MB Source: operationalmanagementsolutions.eu

Sheet 1: FWI

|

|

Reverse FMEA | |||

| [DOCMENT CODE/ REVISION] | ||||

| Form work instruction | ||||

| 0. General | ||||

| The goal of this form is to facilitate the implementation of R FMEA by follwing the following steps: | ||||

| Plan your study | ||||

| Realize analysis | ||||

| Prepare analysis - review operations list, prepare questionaires by using actual identified failure modes. Place: Meeting room |

||||

| Perform analysis - test the workstation! Place: Workstation |

||||

| Perform process observation Place: Workstation |

||||

| Debate and conclude | ||||

| Report R FMEA Activity | ||||

| Use activity report to document R FMEA related activities. | ||||

| R FMEA activity report | ||||

| 1. Content | ||||

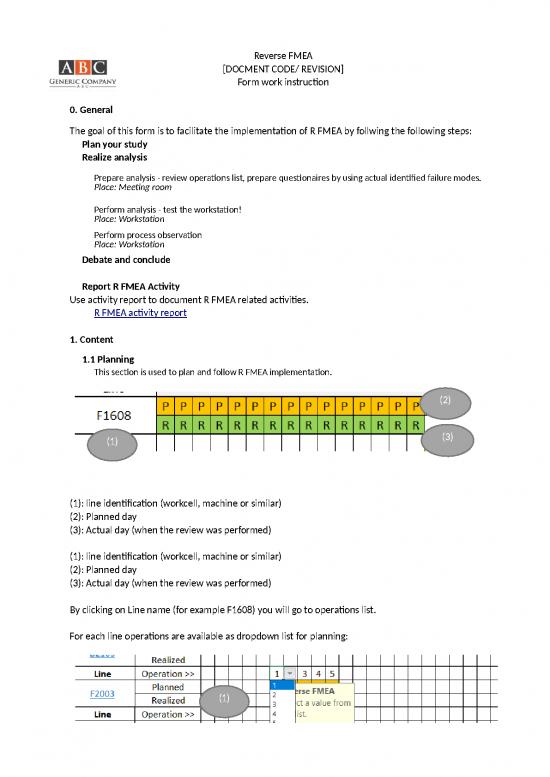

| 1.1 Planning | ||||

| This section is used to plan and follow R FMEA implementation. | ||||

| (1): line identification (workcell, machine or similar) | ||||

| (2): Planned day | ||||

| (3): Actual day (when the review was performed) | ||||

| (1): line identification (workcell, machine or similar) | ||||

| (2): Planned day | ||||

| (3): Actual day (when the review was performed) | ||||

| By clicking on Line name (for example F1608) you will go to operations list. | ||||

| For each line operations are available as dropdown list for planning: | ||||

| When planning or updating status you will need to select the operation - (1). | ||||

| ! | If the line is planned to be stopped R FMEA will be planned for in-station review and not for observation. | |||

| Document your R FMEA team in this section: | ||||

| R FMEA Local Team | ||||

| On-site P FMEA review | ||||

| 1. check Process FMEA vs. Flow chart in workshop. | ||||

| Create/ update operations list. | ||||

| 2. Document actual failure modes from P FMEA | ||||

| Use Operation CheckList | ||||

| Check actual controls effectiveness. | ||||

| Try to indentify new failure modes. | ||||

| - initial checklist preparation - use brainstorming to find new failures - go in the process and: - check control effectiveness - check failure modes - try to think about other faillure possibilities |

||||

| There are 2 possibilities to work with this form when you prepare and update operation checklist: | ||||

| (1) - document each operation in a separate sheet | ||||

| Operation Checklist | ||||

| (2) - document operation by using Process CheckList (all operations in one sheet) | ||||

| Process CheckLIst | ||||

| (1) Operations checklist | ||||

| (1) - operation number and name | ||||

| (2) - R FMEA team | ||||

| (3) - Potentia failure mode analysis | ||||

| () - identififed failure mode [HOW]: describe here how it can occurs based on workstation review. | ||||

| () - if it can occurs, defines how it can be detected or prevented, if prevention is installed. | ||||

| (4) - defines where the failure mode is detected or prevented (at workstation/ downstream or no detection) | ||||

| -review in room P FMEA, prepare the preliminary list by thinking about other failure modes (use brainstorming) | ||||

| - review the workstation, try to find other failure modes then document in the list | ||||

| Review results will be transferred as conclusion in work station evaluation. | ||||

| (2) Process checklist | ||||

| The logic is same as for (1) Operations checklist. Difference is that all operations are centralized in the same sheet. | ||||

| 3. Observe the process | ||||

| With your team go and see the process. Write down your remarks by using: | ||||

| Observation form. | ||||

| - see how the process is going | ||||

| - write what is happening in the workstation by using the form: | ||||

| (2) - workstation and line/ process | ||||

| (3) - FMEA study | ||||

| (4) - Observations/ Time | ||||

| (4.1) - write what you have remarked during observation of the process | ||||

| (4.2) - time (duration in seconds or other time unit) | ||||

| (5) - count each occurence with | | ||||

| (6) - total count of occurences | ||||

| (7) - number of observed cycles | ||||

| Results of observations will be transferred as conclusion in work station evaluation. | ||||

| 4. Final conclusions | ||||

| Discuss your remarks during a short meeting then document your conclusions in the final form. | ||||

| Rank the operation accordingly following matrix: | ||||

| Use the following sections according your implementation: | ||||

| - workstation assesment | ||||

| - process view: check list assesment | ||||

| Template by: | ||||

| This free template comes without any warranty for the user. | ||||

| If there are software modules, functions, classes used it comes without any warrany for the user. | ||||

| according GNU GPL V3 license | ||||

| Planning| Reverse FMEA (Automotive Process Lines) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| [DOCUMENT NUMBER]/[REVISION] | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Company name: | Site: | Date: | Monday, March 01, 2021 | P | Planned | E | Realized | S | Line stopped | R Replanificat | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A se nota motivul în câmpul observații. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Team |

|

2021 Weeks >> |

WK1 | WK6 | Observatii | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Operation | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | L | M | M | J | V | |||

| Local Team | Line | Operation >> | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Injection | Planned | P | P | P | P | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Realized | E | E | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Local Team | Line | Operation >> | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Assembly | Planned | P | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Realized | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Local Team | Line | Operation >> | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Machining | Planned | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Realized | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Local Team | Line | Operation >> | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| General | Planned | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Realized | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R FMEA Planning|Operations List(Process steps) | ||||||||

| [PLANT] Processes | ||||||||

| Injection | Assembly | Machinining |

|

|||||

| Number | Description | Number | Description | Number | Description | Number | Description | |

| 10 | Raw material incoming inspection | 10 | 10 | 10 | Operation 1 | |||

| 20 | Raw material stockage& identification in Warehouse | 20 | 20 | 20 | Operation 2 | |||

| 30 | Mould preparation &setting parameters | 30 | 30 | 30 | Operation 3 | |||

| 40 | Injection | 40 | 40 | 40 | Operation 4 | |||

| 50 | Packaging | 50 | 50 | 50 | Operation 5 | |||

| 60 | Products transfer in warehouse | 60 | 60 | 60 | Operation 6 | |||

| .. | .. | 70 | 70 | 70 | Operation 7 | |||

| Go to CheckList | ||||||||

no reviews yet

Please Login to review.