167x Filetype PDF File size 0.67 MB Source: msh.org

Part I: Policy and economic issues Part II: Pharmaceutical management Part III: Management support systems

Planning and administration

Organization and management

43 Security management

44 Medical stores management

45 Hospital pharmacy management

46 Pharmaceutical management for health facilities

47 Laboratory services and medical supplies

Information management

Human resources management

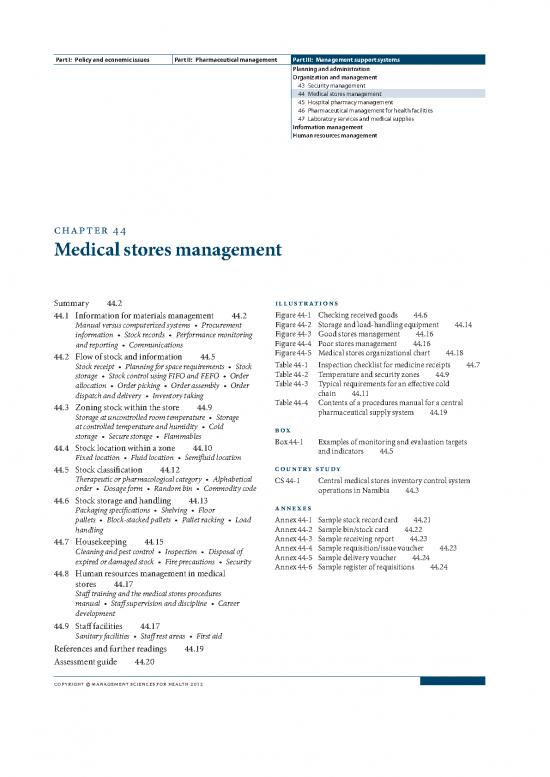

chapter 44

Medical stores management

Summary 44.2 illustrations

44.1 Information for materials management 44.2 Figure 44-1 Checking received goods 44.6

Manual versus computerized systems • Procurement Figure 44-2 Storage and load-handling equipment 44.14

information • Stock records • Performance monitoring Figure 44-3 Good stores management 44.16

and reporting • Communications Figure 44-4 Poor stores management 44.16

44.2 Flow of stock and information 44.5 Figure 44-5 Medical stores organizational chart 44.18

Stock receipt • Planning for space requirements • Stock Table 44-1 Inspection checklist for medicine receipts 44.7

storage • Stock control using FIFO and FEFO • Order Table 44-2 Temperature and security zones 44.9

allocation • Order picking • Order assembly • Order Table 44-3 Typical requirements for an effective cold

dispatch and delivery • Inventory taking chain 44.11

44.3 Zoning stock within the store 44.9 Table 44-4 Contents of a procedures manual for a central

Storage at uncontrolled room temperature • Storage pharmaceutical supply system 44.19

at controlled temperature and humidity • Cold box

storage • Secure storage • Flammables Box 44-1 Examples of monitoring and evaluation targets

44.4 Stock location within a zone 44.10 and indicators 44.5

Fixed location • Fluid location • Semifluid location

44.5 Stock classification 44.12 country study

Therapeutic or pharmacological category • Alphabetical CS 44-1 Central medical stores inventory control system

order • Dosage form • Random bin • Commodity code operations in Namibia 44.3

44.6 Stock storage and handling 44.13 annexes

Packaging specifications • Shelving • Floor

pallets • Block-stacked pallets • Pallet racking • Load Annex 44-1 Sample stock record card 44.21

handling Annex 44-2 Sample bin/stock card 44.22

44.7 Housekeeping 44.15 Annex 44-3 Sample receiving report 44.23

Cleaning and pest control • Inspection • Disposal of Annex 44-4 Sample requisition/issue voucher 44.23

expired or damaged stock • Fire precautions • Security Annex 44-5 Sample delivery voucher 44.24

44.8 Human resources management in medical Annex 44-6 Sample register of requisitions 44.24

stores 44.17

Staff training and the medical stores procedures

manual • Staff supervision and discipline • Career

development

44.9 Staff facilities 44.17

Sanitary facilities • Staff rest areas • First aid

References and further readings 44.19

Assessment guide 44.20

copyright management sciences for health 2012

©

44.2 ORGANIZATION ANd MANAGEMENT

suMMary

This chapter discusses medical stores management at The following are characteristics of a well-managed

central-level stores and at regional or district-level stores stores operation—

that are independent from health facilities. This supply • The store should be divided into zones that provide

model represents the traditional top-down system that a range of environmental conditions and degrees of

is operated by a governmental or parastatal entity or a security.

nongovernmental organization; however, a number of • There should be an appropriate zone to suit every

countries have now decentralized many of their pharma- item to be stored.

ceutical sector operations, including stores management. • Stock should be arranged within each zone accord-

Chapter 8 discusses supply chain options, including the ing to some orderly system.

trend toward decentralization. In addition, many supply • Stock should be stored off the floor on pallets, on

systems contract out certain operations to private-sector pallet racks, or on shelves. Each of these systems

companies. Managing contracts requires skills such as requires specific types of handling equipment.

defining and monitoring performance indicators and • Good housekeeping—cleaning and inspection, the

negotiating payment and service terms. See Chapter 39 disposal of expired and damaged stock, recording

for more information on contracting. The tenets of this of stock movements, and the management of secu-

chapter, therefore, apply to stores operating in either the rity—should be maintained.

public (often called central medical stores) or nonpublic • The management structure should be clearly

sectors. defined.

Medical stores management should assist both the flow • Staff should be appropriately qualified, trained, dis-

and reliability of supplies from source to user as eco nomi- ciplined, and rewarded.

cally and reliably as possible, and without significant • Clearly written procedures and handbooks should

wastage, loss of quality, or theft. The primary purpose be available.

of a store is to receive, hold, and dispatch stock. This • To promote efficiency, staff should have good work-

materials management process is implemented through ing conditions and facilities.

inventory control and warehouse management systems, • Stock should be verified regularly and periodic

which may be manual or computer based. The primary audits should be conducted.

purpose of inventory control is to manage stock and Although the essential characteristics of materials man-

ensure the smooth flow of goods by determining what, agement are the same for all systems, the level of sophis-

how much, and when to order stock. Consequently, it tication of medical stores varies widely, and each store

provides essential information for procurement manage- approaches its system and documentation differently.

ment. Warehouse management comprises the physical Therefore, the basic features presented in this chapter are

movement of stock into, through, and out of a medical adaptable, depending on the complexity of the medical

store warehouse. The systems should also be designed to stores management operation.

provide information for performance monitoring.

44.1 Information for materials management 2. A warehouse management system monitors the physi-

cal flow of goods within the system, such as receipts,

The goals of medical stores management are to protect storage, and issues.

stored items from loss, damage, theft, or wastage and to 3. A performance monitoring system checks that the sys-

manage the reliable movement of supplies from source to tems are operating effectively.

user in the most economical and expeditious way. Effective

management of information is the key to achieving these Information is essential to management (see Chapter

goals. The integrated process is known as materials manage- 49). Collecting, processing, and disseminating informa-

ment. A fully developed system has three key components— tion may seem costly, but the cost of developing and main-

taining an information system should be balanced against

1. An inventory control system ensures that the right the costs of ineffective inventory control (see Chapter 23).

goods are acquired, in the correct quantities, monitors The design of the information system is important, but its

their quality, and minimizes the total variable cost of success depends primarily on well-trained, organized, and

operations (see Chapter 23). supervised staff. Country Study 44-1 describes some of the

44 / Medical stores management 44.3

inventory control system challenges to the central medical to be accomplished more rapidly, accurately, economically,

stores in Namibia. and flexibly. Even with a computerized system, data must

be entered, manipulated, and interpreted by skilled and

Manual versus computerized systems knowledgeable staff.

The information system must include data on products Procurement information

entering and leaving the warehouse, products in stock,

products on order, and ways to monitor the progress of The procurement process (Chapters 18–21) involves medi-

orders in the supply pipeline. Key elements of the system are cal stores input at all levels of the distribution system. These

well-designed forms, computerized information systems, inputs are described below.

and clearly defined procedures. Procurement can be handled from a department within

Two decades ago, most public supply systems relied the medical stores or from an external unit. The medical

completely on manual stock records, but now, many pro- stores unit provides the (internal or external) procurement

grams have changed to computerized systems. Even with unit with a list of the types and quantities of medicines

computerization, however, many countries still maintain needed for its operation. After a supplier is selected and a

a manual system, such as bin cards, as a backup, espe- purchase order is placed, the procurement unit informs the

cially during the transition to computerization. There is a medical stores unit about suppliers, unit prices, the quanti-

widely held belief that computerization solves the problem ties on order, the expected arrival dates of shipments, and

of inventory control. This belief is misguided. A computer other vital information.

is not a substitute for trained staff; it is simply an addi- The procurement unit tracks information on inventory

tional tool for staff to use (see Chapter 50). Both manual status, new shipments received and taken into stock, issues

and computerized systems perform the same fundamental made to health facilities, expired medicines, damaged medi-

information-processing tasks: data input, data storage, data cines, and audit data from physical stock checks.

processing, data retrieval, and data dissemination. The dif- The medical stores unit also tracks issues to individual

ference is that a computerized system enables some tasks health facilities, noting methods of transport, delivery

Country study 44-1

Central medical stores inventory control system operations in Namibia

Namibia operates a classic central medical stores (CMS) A computerized inventory control system had been

distribution system with a CMS and two regional medi- installed at the CMS several years earlier, but most of the

cal stores. Administratively, the regional stores do not staff members who were initially trained to use it had left

have any links with the CMS—the relationship between the public service; remaining staff members, therefore,

them is one of customer and client. The CMS distrib- were not using the system to its full advantage. Many

utes medicines and supplies to the two regional medical functions that could have been handled by the system

stores, all district hospitals, and local hospitals and clinics were done manually or with spreadsheets. Moreover,

in the surrounding regions, while the regional stores and management personnel reported that they did not have

district hospitals are responsible for distributing to other enough time to acquire the additional skills that would

facilities within their geographic jurisdictions. help them use the system.

Facilities are expected to order products from CMS every As a result of the CMS assessment, a number of recom-

six weeks, and it usually takes CMS about four weeks mendations to improve the inventory control system

to process and deliver the order. An assessment of the were made: conduct complete physical inventory counts

CMS distribution showed, however, that stock records at all levels and use the results to update or introduce

were not adequately maintained and physical inventory stock records; develop standard operating procedures for

counts did not correspond with either stock records or store management; and train staff on how to maintain

computerized records. Because the regional stores and stock records and use the computerized inventory con-

health facilities had no effective systems for deciding trol system to their best advantage.

when, what, or how much to order, most facilities ended Source: Management Sciences for Health/Rational Pharmaceutical

up placing many emergency orders within the six-week Management Plus Program.

order period, which stretched the capabilities of the

already overburdened CMS.

44.4 ORGANIZATION ANd MANAGEMENT

times, and confirmation of receipts from user units. This When a shipment of medicines is received at the CMS, it

tracking should generate information on the monthly and is inspected to ensure that it meets the specifications in the

annual value of total issues, issue quantities, details of spe- supply contract. If the shipment is satisfactory, the receiving

cific products, and how budget allocations are used. section of the warehouse produces a receiving report (see

After an order has been placed, its progress should be Annex 44-3). This report brings the procurement lead-time

monitored until it is received at the central medical stores period to an end.

(CMS). A good monitoring system makes it possible to Individual health facilities are the end users of medi-

estimate realistic delivery times and to decide whether any cal supplies. Maintaining information from health facili-

supplementary or emergency orders are needed, well before ties is essential in order to monitor consumption, forecast

a stockout occurs. pharmaceutical requirements, and make other manage-

Both manual and computerized systems should identify ment decisions. Many medical stores information systems

milestones during the lead-time period to facilitate com- also keep general information on facility location, facility

munication with suppliers and to prompt corrective action status, population served, method of distribution, delivery

if required. Important milestones of the procurement lead schedule, value of issues, and extent of current budget uti-

time are— lization.

• Order initiating date Performance monitoring and reporting

• date of award to supplier (for tenders)

• Letter of credit information A store should monitor and evaluate its operations to

• Shipment information and date identify problems in the system that need to be addressed.

• Arrival at port Record-keeping and reporting systems should be designed

• Port-clearing date to make the collection of data for routine monitoring as

• date of issuing a receiving report simple as possible (see Chapter 48). Stock records are a

vital source of information on how effectively the dis-

An effective supplier information system should include tribution system is being managed; therefore, maintain-

general information on suppliers and products, lead times, ing these records accurately and keeping them up-to-date

merit ratings, value of purchases, product quality, payment is vital. They provide detailed evidence of how prod-

methods, and prequalification based on good manufac- ucts flow through the system and can be used to identify

turing practices. Information about supplier performance where problems are occurring so that corrective action

should be compiled throughout the procurement cycle to can be taken. Operational indicators can track progress

assist in choosing future suppliers. Chapter 21 discusses at two critical levels: from the supplier to the store, or

the features of a procurement information system in more “upstream,” and from the store to clients, or “downstream.”

detail. Upstream information includes lead-time from supplier

to the store, number of medicines procured, and monthly

Stock records stock status reports. At the downstream level, the store

should collect routine lead-time information; distribution

Stock records contain information about suppliers, custom- information by facility, district, and product; client sat-

ers, prices, stock receipts, stock issues, stock losses, and stock isfaction and consumption data; and order-fill rate. Box

balances. These data are essential for planning distribution. 44-1 shows a list of sample indicators. The medical stores

A stock record (manual or computerized) must be main- should prepare regular reports on stock and order status,

tained for each item in the inventory. The stock record docu- such as those described in Chapter 23, and send them

ments all transactions relating to an item. It may contain to relevant parties such as the ministry of health, pub-

information about reorder level, reorder interval, reorder lic health programs, donors, lower-level warehouses, and

quantity, lead time, stock on order, and estimated consump- health facilities.

tion rate. Many stores also maintain bin cards for each prod-

uct in each storage area to record information on issues, Communications

receipts, and stock balances. In some stores, this bin card

is the most current and accurate record of inventory move- The medical stores must maintain effective communica-

ment. tions with suppliers, with procurement and inventory con-

The design of stock cards and bin cards depends on the trol units, with lower-level warehouses and health facilities,

choice of inventory control system. For details regarding and with managers from the ministry of health. Periodic

the design, selection, and use of different types of inventory meetings with the staff members of client facilities can help

control systems, see Chapter 23; examples of a stock record ensure good communications and a more effective supply

card and a bin card are provided in Annexes 44-1 and 44-2. system.

no reviews yet

Please Login to review.