188x Filetype PDF File size 0.19 MB Source: jiei.stb.iau.ir

Journal of Industrial Engineering International Islamic Azad University, South Tehran Branch

June 2009, Vol. 5, No. 9, 27-36

S. Raissi*

Dep. of Industrial Engineering, Islamic Azad University, South Tehran Branch, Tehran, Iran

Abstract

Multivariate Process Capability Indices (MPCI) show how well a manufacturing process can meet specifica-

tion limits when quality characteristics enclose a relative correlation. Process capability is an important and

commonly used metric for assessing and improving the quality of a production process. When quality charac-

teristics of a product are correlated then an attractive comes close to MPCI methods, which are not usually an

easy task to carry out. In this investigation after a full reviewing of the MPCI, a simple method to estimate

product capability indices based on ridge regression models in the presence of priority for quality characteris-

tics is presented. The technique is demonstrated for evaluation of product capability through the use of an ex-

ample which shows performance of the proposed method.

Keywords: Multivariate process capability indices; Product capability; Ridge regression method; Quality

characteristic priority; Multivariate statistical process control

1. Introduction which are effective tools for quality assurance.

These indices are defined as:

Process produces products according to a certain

quality characteristic, for example weight, length, USL−LSL

C = i

hardness, viscosity, etc. The degree a process is P 6σ

producing data within tolerance limits, can be

measured using Process Capability Indices (PCIs). USL −µ µ−LSL

C =Min ,

PCIs are generally used in industry to measure cha- PK 3σ 3σ

racteristics that are independence of each others. A

standard practice in Statistical Process Control

(SPC) programs is to ensure that the process is un- C = USL−LSL i =1, 2, ..., p (1)

PM 2 2

der statistical control prior to conducting a process 6 σ +(µ−T)

capability analysis. Unfortunately, it is a fairly

common practice to perform capability analysis

using a sample of historical process data without C =Min USL−µ , µ−LSL

PMK

any consideration of whether or not the process is in 3 σ2+(µ−T)2 3 σ2+(µ−T)2

statistical control. As Montgomery [25] stated, if

the process is not in control then its parameters are

unstable and the value of these parameters in the where USL and LSL are the upper and the lower

future is uncertain. Hence, the predictive aspects of specification limits, respectively, µ is the process

the process capability indices regarding the number mean, σ is the process standard deviation and T is

of nonconforming items produced are lost. target amount anywhere within the specification

The most frequently used univariate PCIs includ- interval.

ing C , C , C , and C have been proposed in PCIs have recently received a considerable

P PK PM PMK

the manufacturing industry to provide numerical amount of attention in the literature of SPC. Nu-

measures on process capability and performance, merous authors including Kane [20], Marcucci and

* Corresponding author. E-mail: raissi@azad.ac.ir

Beazley [24],Chan and Cheng [3], Choi and Owen 2. Some techniques in MPCIs evaluations

[8], Spiring [37],Koons [21],Wheeler and Cham-

ber [43], Pearn [32], Bissel [2], Wright [45], Pearn Various authors have proposed alternative ap-

and Chen [29], Stoumbos [38], Pearn and Shu [33], proaches to assess process capability in multivariate

Chen and Chen [6], Perakis and Xekalaki [34] and environment. Taam et al. [39] recommend using a

Chou et al. [10] have discussed theories and appli- multivariate capability index that is defined as a

cations of univariate PCIs, when process normally ratio of two volumes:

distributed.

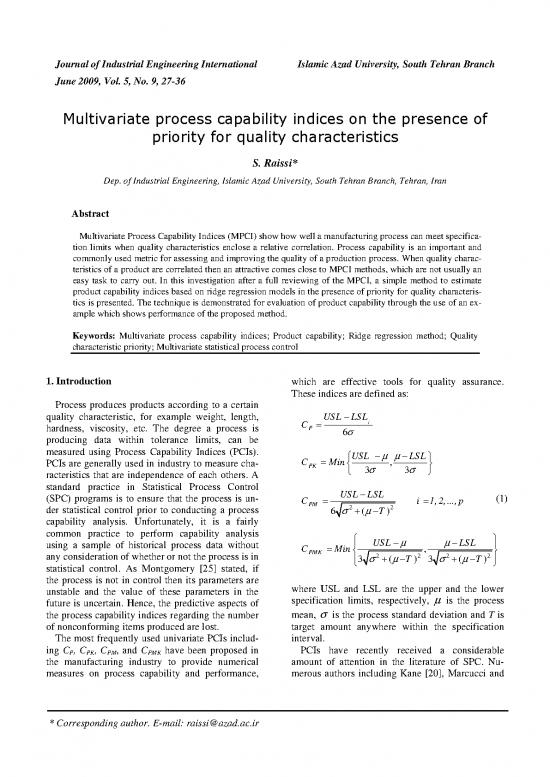

Extensive studies have also been conducted to de- Vol.(R )

MC = 1 (2)

termine the effects of non-normality on the various PM Vol.(R )

PCIs. Gunter [13,14,15,16] in a series of articles 2

pointed out many flaws of the indices particularly

where R is a modified tolerance region and R is a

C when applied to non-normal data. Interested 1 2

PK

readers are referred to Munechika [26], Clemets scaled 99.73 percent process region. In particular, if

[11], Wright [44], Somerville and Montgomery the process data are multivariate normal, then R2 is

[36], Bai and Choi [1], Chen and Ding [7] and an elliptical region. A process region and modified

Chou et al. [9] for more discussions on the univa- tolerance region is shown in Figure 1 at appendix.

riate process capability indices when normality as- The modified tolerance region is defined as the

sumption is violated. largest ellipsoid that is centered at the target com-

During the past decade, there has been a growing pletely located inside the original tolerance region.

The estimate for MC is given by:

concern about the normality and independence as- PM

sumptions required to compute univariate capability

indices. In practice, it is common to use two or ˆ

ˆ CP

more related quality characteristics of a product to MCPM = ˆ (3)

evaluate the performance of a manufacturing D

process. Since the early work of Hotelling [17], it

has become evident that such problems, due to the where,

correlation that exists among quality characteristics,

need to be addressed in multivariate context to en- ˆ Vol.(tolerance region)

CP =

sure proper evaluation. Similar to the univariate Vol.(estimated 99.73% of process region)

case, the Multivariate Process Capability Indices Vol.(tolerance region)

(MPCIs) have also captured attentions of many re- = ν −1 (4)

1 ν

searchers including Hubele et al. [19], Chan et al. S 2(πK) 2 Γ( +1)

[4], Taam et al. [39], Nickerson [27], Chen [14],

2

Karl et al. [23], Niverthi and Dey [28], Shahriari

et al. [35], Wang et al. [42], Wang and Du [40], and,

Frey et al. [12], Wang and Hubele [41], Pearn et al.

[31] and Pearn and Chien-Wei [30]. For a quick 1

ˆ n ′ −1 2

survey and interpretations on univariate and multi- ( ) ( )

D= 1+ X−0 S X−0 (5)

n−1

variate process capability indices see Kotz and

Johnson [22].

An existing serious problem in multivariate quali- where K is the 99.73 percent quantile of a χ 2 dis-

ty control is in complexity of methodology for as- S

sessing MPCIs. The purpose of this paper is to pro- tribution and denotes the determinant of sample

vide a relatively simple method for estimating the variance-covariance matrix.

most well-known relevant PCIs (priory showed Shahriari et al. [35] proposed a vector consisting

through set of Eq. (1) in multivariate environment of three components. The first two components use

which define by MC , MC , MC , and MC the assumption that the process data is from a mul-

P PK PM PMK

respectively. A brief discussion to some MPCIs is tivariate normal distribution with elliptical contours

presented in Section 2 and the proposed methodol- defining probability regions and the third compo-

ogy to estimate MPCIs are offered in Section 3. The nent is based on a geometric understanding of

fourth part discusses a numerical example. Conclu- process relative to the engineering specifications.

sions are provided in the final section. The first component is defined as:

1 F denotes the value of F distribution with

vol. of engineering tolerance region ν (ν ,n−ν )

MCPM =

ν and n-ν degrees of freedom. It should be pointed

vol. of modified process region

out that large values of PV indicate the closeness of

1 the center of the process to the pre-specified target

ν ν

∏(USL −LSL )

value.

i i The third component of the vector that is referred

=

i =1

i =1,2,...,ν (6)

ν

to as location index (LI) compares the location of

∏(UPLi −LPLi)

the modified process region to the tolerance region.

i =1

This index has a value of one if the entire modified

process region is contained within the tolerance re-

Figure 2 at appendix illustrates their method for a gion indicating that all the manufactured products

product in which the engineering specifications de- conform to the specification limits, otherwise it will

fine a rectangular tolerance region but bi-variate take a value of zero.

normal process variables define an elliptical proba- Chen [5] proposed a multivariate process capabil-

bility contour referred to as process region. Their ity index based on a multiple bilateral tolerance

proposed method forms a modified process region zone defined by:

by drawing the smallest rectangle around the ellip-

tical process region. The edges of the modified { V }

V = X∈R : X − ≤r,i=1,2,....,v (11)

process region are defined as the lower and upper i 0 i

process limits (LPLi and UPLi, respectively, where

i=1,2,…ν) and are given by: where µ is the specification limit and r is a con-

0i i

stant. The multivariate process capability index is

χ2 −1 given by MC = 1 , where r is defined such that:

UPL =µ + ν,α i P r

i i −1 (7)

X −

i 0

i

2 −1 P Max r ,i =1,2,...,v ≤r =1−α (12)

χ i

ν,α i

LPL =µ − ; i = 1,2,...,ν (8)

i i −1

Let F be the cumulative distribution function of,

2 α

where χν,α denotes the upper 100( ) % of X −

i 0

aχ2distribution with ν degrees of freedom and h(X− )=Max i ≤r,i=1,2,....,v (13)

0 r i

i

−1

i is the determinant of the variance-covariance

matrix with its ith row and column deleted. −1 MC

Then r = F (1−α). If the value of P is

The second component of the proposed vector is greater than or equal to 1, the process is capable

based on the assumption that the center of the speci- with a certain confidence level.

fication limits denotes the process mean. This com- Frey [12] proposed a matrix of dimensionless pa-

ponent is defined as the significance level of a Ho- rameters (C), which represents a linear mapping of

telling’s T 2 statistic, which is computed as follows:

noise variables (nj ; j=1,2,…,n) to quality characte-

ristics (qi ; i=1,2,…,m), for evaluating process ca-

2 ν(n−1) pability in multivariate environment. The elements

PV = PT ≥ F (9)

n−ν (ν ,n−ν ) of this matrix, C , are defined as:

ij

where, ∂q

6Sj

∂n

′ −1 n=t ij

T2 = n(X − ) S (X − ) (10) C = (14)

0 0 ij USL −LSL

i i

Figure 1. Typical modified tolerance region (R1) versus estimated 99.73 % process region (R2) in a bivariate case.

Figure 2. Rectangular Tolerance Region versus Modified Process Region.

no reviews yet

Please Login to review.